OUR BLOG

Like any coffee roaster, the Roest needs a bit of maintenance from time to time to keep it in top condition. So, if your Roest has worked hard for you all year, why not give it a spa day in return?

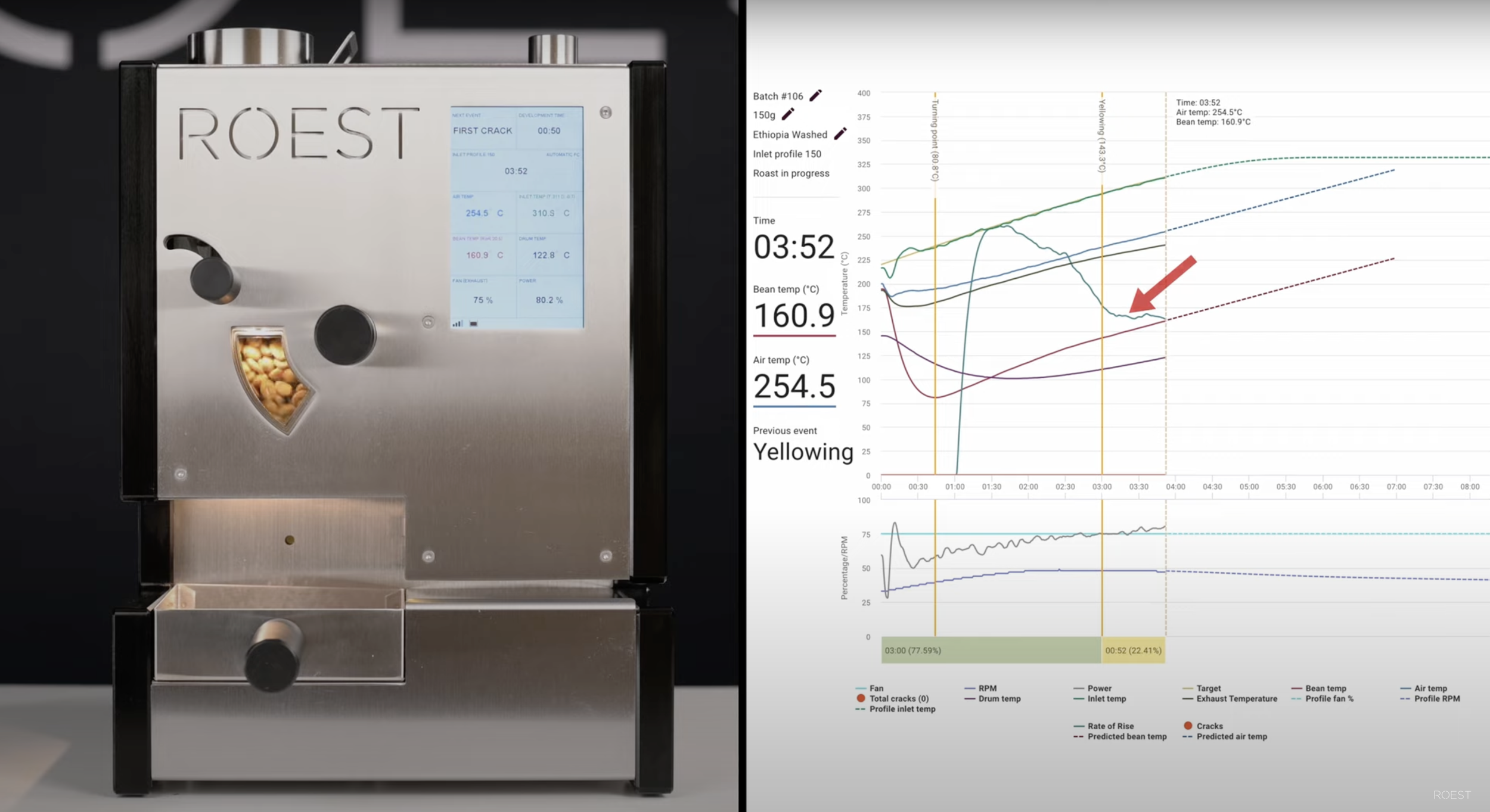

In this post, we’ll share some tips on optimizing your profile, explain why BT/IT profiles are so powerful — and set you up with some sample profiles to start your journey. To kickstart your journey with creating your own BT/IT profiles, we asked some of our early adopters to share what they’ve learned over the last few months of roasting with the new profile type.

Baristatus Co are coffee explorers dedicated to unlocking excellence with the ROEST sample roaster. With their non-profit model and three special categories, they curate the best coffees for enthusiasts worldwide. The ROEST empowers them to achieve precision, experiment, and fuel their growth. Join the revolution and elevate your coffee experience.

Behind every exceptional cup of coffee lies a meticulous process of roasting. Paying attention to details during the roasting process is paramount. One crucial parameter to control and achieve optimal results is the Rate of Rise (RoR). In this article, we will explore the concept of RoR, its significance in coffee roasting, how to calculate it, and its relevance at different stages of the process.

Our sample roasters perform the same way each and every time that you roast - but sometimes, the green beans have other ideas. Every batch of beans is slightly different, even if you pull them from the same bag.

The solution is a roast profile that adapts itself to how the beans respond by adjusting the amount of heat according to what stage of the roast the beans have reached. You can do this with Bean Temperature/Inlet Temperature (BT/IT) profiles, a new feature included in our latest firmware update.

We're thrilled to bring you the latest news on the P3000, our next leap in coffee roasting technology.