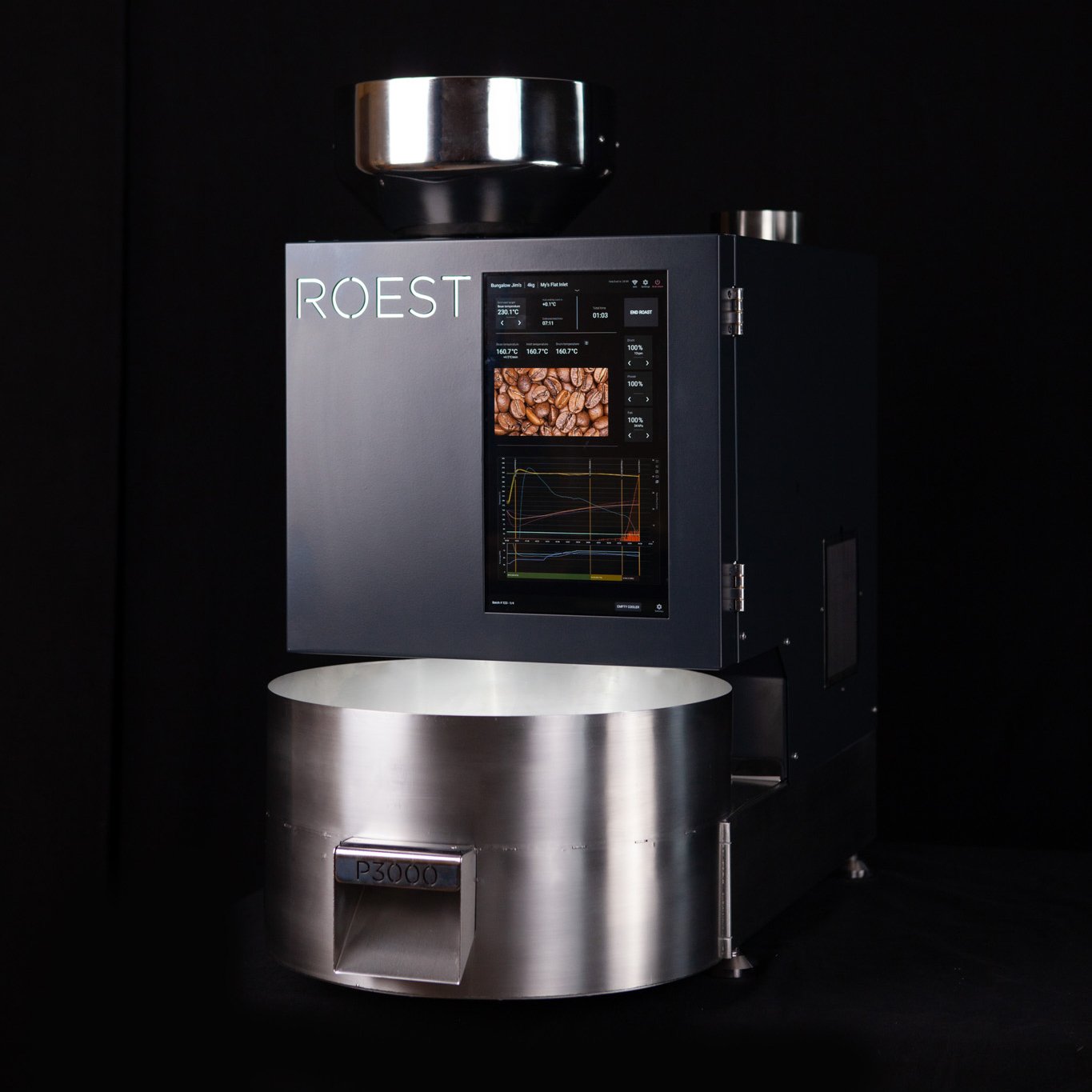

Updates on P3000 - the Automated Production Roaster

We're thrilled to bring you the latest news on the P3000, our next leap in coffee roasting technology.

We know that many of you have been waiting for an update on the development of our P3000, and we appreciate your patience. It’s been a year of constant improvements, and today, we are happy to share our latest update, including an estimated timeline for production start, shipments, and scaling of production.

About the P3000

The P3000 is a 3kg user-friendly coffee roaster designed for simplicity and precision. It offers full automation, easy maintenance, and consistent results. It’s a robust coffee roaster, making it ideal for demanding production environments — and easy to learn for new coffee roasters.

The P3000 is a reliable tool for coffee roasting, equipped with advanced sensors to ensure predictable roasting results. Its design focuses on even heat distribution for unparalleled consistency between batches. You won’t be able to taste the difference between two batches of the same coffee roasted with the same profile on the P3000.

Today’s Status

Our team has been constantly working on the P3000 prototype, improving and developing its features. The most significant change since our last update in early 2023 has been the refinement of the P3000’s feature set, as detailed below. It’s all the small things combined that make a great user experience.

As you all know, quality is our biggest priority, and we're dedicating as much time as needed to ensure that the P3000 meets our high standards. Please note that this timeline is an estimate, and changes may occur.

Estimated timeline:

Pilot phase from April 2024

In the pilot phase, a few selected partners will test the P3000 in their own roasteries.Production start September 2024

We are planning on starting production of the P3000 in the autumn. If everything goes as planned, the first units will be shipped out by late autumn of 2024.

Depending on certifications, the P3000 will be shipped to some regions at a later date. More information about this will follow.Scaling of production during 2025

All of our roasters are being produced in Oslo, Norway, and we will begin scaling up our production during 2025.

UPDATED TECHNICAL INFORMATION

Power requirements

We will offer the machine in two versions:

single-phase 230v 32A (7.1kW)

three-phase 400v 16A (10.24kW)

The main difference between them is the heating elements rating and how the machine is wired/configured. It’s possible to re-configure the machine between the two versions.

With the highest-rated version, a full batch size can reach the first crack in 5 minutes.

UPDATES ON THE ADD-ON UNITS

Electric afterburner

We have a functional prototype of the smoke reduction system, and a more refined version is in development. As the capacity of our machine has increased, the power consumption of our afterburner has increased. Our goal is to be able to effectively reduce visible smoke and odor from the roasting process with the power accessible from a single 16A, 230V socket. Easy access for service and maintenance is a high priority as always.

Adjustments to the feeding unit

As promised in our last update on the P3000, there will be a custom feeding unit for the machine that can store up to 100 kg of green coffee and automatically vacuum feed it to the roaster based on your profile weight. The prototype unit is working, and we have a new, improved design ready for pre-production in the coming months.

SENSOR UPDATE

The P3000 collects a lot of data during roasting, and we are constantly looking for ways to improve. For coffee roasting, temperature is still the most fundamental parameter to have control over. It’s no secret that we have added a lot of sensors to the P3000.

Bean temperature

There are two different types of BT sensors. One is super-fast and accurate. The other is stable over time and super accurate. Combining these two sensors, we get the most accurate BT reading possible. We are adding one of each sensor to each side of our symmetrical roasting chamber and giving the user the average of all four sensors.

To achieve the accuracy we are looking for we are developing a calibration chamber to calibrate each bean temperature sensor in house.

Drum temperature

An average of three sensors measures the surface temperature of the roasting chamber drum, located at optimal points along the drum and combining two different types of sensor for the highest accuracy and stability over time.

We can see that the drum temperature stabilizes after an appropriate heat-up or a few batches of coffee. It then follows the coffee roasting process cycle without overheating throughout the day.

Inlet temperature

Having control of the heat going into the roasting chamber is critical for a precision tool like P3000. For an even heat distribution, we are using three heating elements in a row. These are located outside the roasting

chamber, with a pre-mixing chamber for the cold incoming air and a pre-mixing chamber for the heated air going into the roasting chamber (through holes in the drum wall). To control the temperature precisely, each heating element has two custom sensors arranged in opposite locations. This grid of six sensors and an optimised PID ensures the inlet temperature follows your profile exactly.

First crack

First Crack detection in the P3000 proved a challenge as the roasting chamber has a positive pressure inside. We have overcome this problem, and are fine-tuning the algorithm to work across batch sizes and coffees. Development and deployment of more advanced models has been made possible by our integration of OTA (over the air) updates for the first crack module.

Camera

The P3000 integrates a bean camera which displays real-time images of the beans in the drum, replacing a traditional trier. In order to achieve maximum consistency across batches it is essential to remove the destabilising effect of triers on the roasting system. Camera integration is the basis for a suite of future tools to aid decision making, and eventually influence the control system. Colour tracking, the first feature which will be released, gives an indication of the rate of colour change indicative of the velocity of the roast.

As we gear up for the pilot phase and begin planning for production, we remain focused on quality and innovation. Stay tuned for more developments, and thank you for joining us on this journey.

Remember to sign up for our waiting list if you are interested in our P3000 roasting machine!