Roasting whiskey barrel-aged coffee - from sample to sales

Green coffee industry is improving and developing new techniques in order to bring to our customers new flavor experiences. Is your coffee roasting improving along? Roasters are constantly facing new challenges with a trend of experimental approach to processing. Have you ever tried roasting coffee sample that was soaked in whiskey oak barrels?

Over to Adam:

Hi my name is Adam and I’d like to tell a story about a recent whiskey barrel-aged coffee project that I led from creation to sales. Vike, my sample roaster ROEST S100, had a special role to play.

Adam with his ROEST sample roaster named Vike. All ROEST roasters are named after places in Norway.

With high value coffee it’s great to have a reliable sample roaster in order to find the best roast profile and reduce cost of failures. Roasting coffee on sample roaster provides an idea on how to develop the full potential of my coffee. It also gives me an overall understanding of how the coffee reacts to certain roast profiles.

At the end, I provided an exercise for further roast skill discovery and contact info if you have any questions or would like to connect.

“Wow!” coffee strategy

Branch point Oregon wheat whiskey barrels were used for this coffee experiment.

Mid August, I met with a local whiskey distiller to collaborate on a whiskey barrel-aged coffee. Three wheat whiskey barrels were delivered and I committed our Guatemala Monte Cristo coffee for trial. This was going to be a high-value “Wow!” coffee to excite and entice customers sold at USD$20 for an 8oz (227g) bag.

On top of normal sales and marketing duties, I had one month to employ these fresh-hot whiskey barrels to produce an amazing coffee. First I needed to perfect the green coffee ageing, then find an ideal roast profile with ROEST sample roaster, and finally move to roast on a SF-25 (San Fransciscan 25lb) for production and sale.

Soak it until you make it!

Guatemala SHB “Soaking” in Whiskey Barrel

The American Oak barrels showed a 24.5% wood moisture reading while the puddle of whiskey at the bottom smelled of vanilla, honey, clove and caramel. The first test was to take our 10% moisture SHB Guatemalan green coffee and discover how long it should “soak” suspended by mesh bag inside of each barrel to absorb moisture and whiskey aromas.

After successive tests I discovered that it was best to soak the green about 72 hours until it reached 11% moisture content.

Developing roast profile on ROEST

Roasting a high density bean with extra moisture was a challenge. The Standard profile and Nordic profiles both crashed hard and made the coffee flat. I tried more aggressive custom profiles, but they burned the coffee and destroyed all whiskey aromatics.

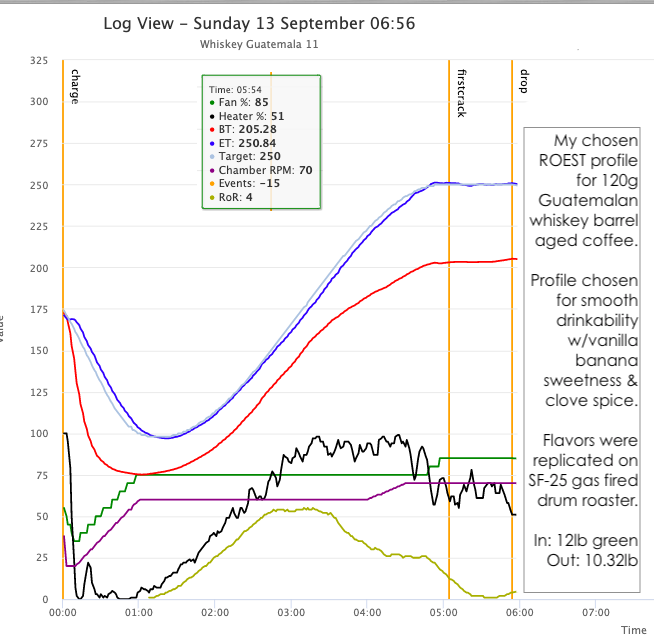

11% Moisture, Dense Whiskey Bean Profile

Finally, on an Air Temperature profile, I chose a low charge temperature at 175°C (350°F) in order to provide a roast soak with a slow turning point. This allowed the internal bean temperature to warm gently and build slow strong momentum to compliment the 11% moisture content.

Increasing the fan and chamber first, I delayed the power increase in order to reach a smooth acceleration. After yellowing I increased the chamber speed (RPM) first to flatten my Rate of rise (ROR) and next increased the fan speed to disperse the ever increasing heat. With a 5:55 roast time I reached 206°C (403°F).

The logic was to use a faster roast to protect the whiskey aromatics. In order to achieve this, I wanted to avoid under development by using the first half of the profile. Second, I needed great power to charge into first crack to avoid losing heat and crashing.

Finally, I anticipated that this process could be replicated on the conductive driven gas fired SF25 drum.

ROEST sample roaster is a hybrid of traditional drum roaster and hot air roaster therefore it is behaving similar to your production drum roaster.

Sweet like a banana with vanilla and clove

The result of the 5:55 Whiskey-11 roasting profile was fantastic. The coffee was clean and crisp, sweet like a banana with vanilla and clove. The team loved it, so it was time to move from sample roasting to production roaster for sale. All this while, I had been promoting online to build anticipation for the unveiling of our whiskey coffee - so customers were ready for fresh batch possible!

Roast profile for you to try!

Here you can copy my roast profile: ROEST sample roaster Whiskey-11

Transferring profile from sample roaster to production roaster

I chose to roast on the SF-25 at 50% capacity - 12lbs green in with a target of 10.32lbs out. The moisture loss of 14% was to replicate what happened on the sample with 120g green in and 103g roast out. This variable needed to remain constant to ensure that a similar process was happening to the beans.

I charged the SF-25 at 350°F (175°C) and let the beans soak nearly 60 seconds before applying 67% gas to ramp up the heat. The damper was 80% open and the fan was at full speed. When I passed yellowing I opened the damper to 100% and slow the ROR slightly with 50% gas.

Roasting on a SF-25 required the 5:55 roast be stretched 1.5x. In order to complete first crack the production roast reached 9:30 at a higher temp of 410°F (210°C) to finish. Moisture loss was 14% and the cupping results were incredibly similar.

The Quality Control team approved and first test customers were amazed. The coffee was sweet, with soft acidity and syrupy body. Whiskey vanilla notes were strong during the brew and aftertaste. The coffee was released and sales quickly exceeded expectations. We sold beans, brews and went big on cold brew for 6 solid weeks of sales.

To sum up

With ROEST sample roaster you can roast both: automatically or manually.

I learned that inverse logic is required to counteract the end of roast crash. A crash at the end, did not imply more heat is needed at the end. This logic destroyed acidity and sweetness. It turned the coffee into a dark boring Guatemala. As you can see on the profile, at 250°C the ET (Air Temperature) holds steady. Another lesson I learned, is that this high moisture high density coffee required a lower charge temperature, deeper dip and soft heat application at the beginning to build internal bean energy and carry the roast up and through first crack.

You need to be able to roast manually small batches: adjust Fan speed, RPM, Power or other parameters in order to direct the roast to the desired cup profile. Sample roasting on ROEST allows me to experiment until I find the best suited profile for my coffee beans.

Your Homework

ROAST DISCOVERY EXERCISE

Start with a reliable roast curve to roast 7 batches of one coffee. Repeat the same profile finishing each batch at: 200°-202°-204°-206°-208°-210°-212°C. Taste how acidity and sweetness peak and where they die off. If you’re lucky, you may find a “dead zone” in certain beans. For example, I have seen that a 206° roast can be wonderful, while the 208° goes flat and then 210° becomes sweet and again. This transition awareness comes from excessive cupping and can lead you to a greater confidence in product creation, promotion and sale.

Share your results with our community on ROEST forum, so that we can all learn together.

Get in touch

If you’d like to connect with questions about barrel-aged coffee or anything else, then please reach out. My new online coffee training, @asc.coffee on Instagram or email me.