Creating 50g profile - detailed report

Blazej was returning from Berlin when the lockdown due to COVID-19 started in Poland. To make the most out of the unexpected situation, and being in quarantine, he decided to improve his roasting skills – creating 50g profile on ROEST.

Over to Blazej:

To give you a bit of my professional background: I've got over 10 years of experience in the coffee industry. The most of my recent activities are based in the coffee community in Poland. Since the beginning of 2019, I’ve started selling green coffee directly from Guatemala in cooperation with 88graines. Here I get to roast daily a lot of coffee samples. I used to roast on the 50g small fluid sample roaster and traditional 100g drum sample roaster. For more than a year, sample roasting was also very helpful for all SCA Coffee Skills - sensory skills courses which I'm running at least 3 times per month. This gives me an experience of roasting more than 500 samples on different sample roasters. Along with roasting courses organized together with the Coffee Mind academy from Copenhagen, I gathered the knowledge to understand that it is possible to roast 50g of coffee in 120g capacity on the ROEST sampler roaster.

The circumstances for creating 50g profile were favorable: One ROEST sample roaster, lockdown in Poland, my home quarantine, a lot of time and green coffee.

I'm very pleased to share with you the process of how I created the 50g roast profile on ROEST sample roaster.

Understanding the roaster

The usual amount of coffee which can be roasted in a traditional drum roaster is 80 to 90 % of the roaster’s maximum capacity. The minimum is 30 to 40 %. In other words, these are the usual amounts of green coffee which can be roasted on a typical production drum roaster. ROEST has a maximum capacity of 120g. 40 % of its capacity is more or less 50g.

Before roasting 50g with the use of ROEST sample roaster, I tested a few 100g environmental-based profiles (ET), which were already developed by other users of ROEST. I can assure you that they are very efficient and easy to use: repetitive, reliable and consistent.

My concern was that most of ET profiles did not give me full control of power management during the roasting process. The roaster can be controlled in two ways; by temperature or power. To control the roaster by power, I had to switch to manual mode.

I started with a few trail batches with a regular 100g profile using 100g of green coffee. After a few trials giving me satisfying results, I decided to roast 50g batch with the same profile. As you can probably imagine, power suitable for the 100g batch was too high for 50g of green coffee. The first batch was totally burnt in less than 5 minutes.

I decided to adjust the profile step by step to figure out how significantly it[AR2] will change the process itself in comparison with the first trial.

Methodology

I made notes of all measured parameters: drop temperature[AR1] , turning point temperature, first crack temperature, end roast temperature (bean and environment), as well as minute by minute bean temperature (BT) and environment temperature (ET). I was also observing rate of rise (ROR) while roasting. It was very helpful for me during each step of the profile modifications.

Below you can find the methodology of the roasting process:

1. Roasting two to three batches of the coffee from three different origins and qualities.

2. Usually, it was the low altitude and low-density coffee from Brazil or Honduras, regular coffee from Colombia or Ethiopia and high altitude, high-density coffee from Colombia or Kenya.

3. After each trial roast, I did a quality check one day after roasting.

4. Then I discussed the details with Lukasz Jura, who was mentoring me through the whole process.

5. I implemented the modifications.

Based on this methodology, this is the process of creating a 50g profile, step by step.

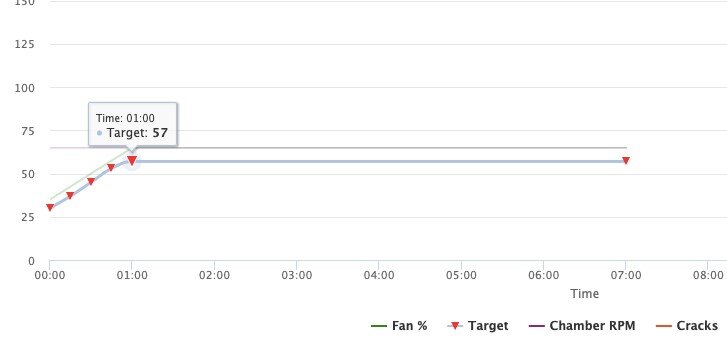

1st profile: I changed the energy from 63 %, which was appropriate for the 100-gram coffee batch, to the power level of 57 %. Additionally, I fixed the drum speed for constant 65 RPM from the beginning until the end of the roast process, to avoid tipping or facing defect.

Drop temperature: 170°C. Development time: 50 seconds.

Effect on the profile: The roasting process became 30 seconds longer than in regular 100-gram power profile. It was still too fast and too aggressive for most coffee which I roast. ROR at the end of roast time was too high.

Cup profile effect: Bitter taste and astringency, too smoky, flat flavor.

What was to improve: lower drop temperature and power reduction with the first crack.

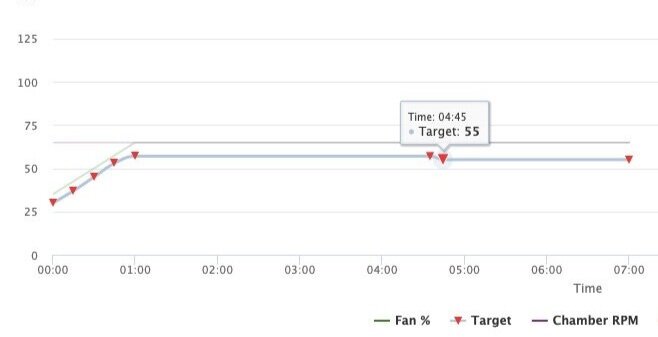

2nd profile: The dropping temperature reduced to 165°C to make the whole process longer. Power was reduced at the moment of the first crack from 57 to 53 % - at about 5:00 minutes. Development time: 50 seconds.

Effect on the profile: No tipping or facing defect in high-density green coffee beans. The whole process took around 6.00-6.15 minutes. I noticed that the ROR, in the middle of the development time after first crack, was too high.

Cup profile effect: Better in taste balance, but still acidity muted and too aggressive. Texture was smoother, but the flavor was still too flat. Some smoky notes when coffee was cooling, not the best aftertaste, usually dry.

What to improve: Better power management before the first crack; reduction of about 15 seconds, and longer development time; up to 60 seconds.

3rd profile: Power reduction to 55 % before the first crack and longer development time; 60 seconds.

Effect on the profile: Process of roasting usually longer; up to 6.30 minutes. More stable ROR after the first crack, but still too high.

Cup profile effect: Aftertaste longer and smoother. Flavour still to flat. Acidity still a bit muted and a bit sour.

What to improve: Fan speed reduction simultaneously with power reduction. Different drop temperatures for coffee with different densities.

4th profile: Higher fan speed, from 65 to 80 %, and optional power reduction within the first crack.

Effect on the profile: Stable ROR after the first crack. More consistent roast for different green coffee densities. When using low-density coffee, ROR after the first crack can be still too high.

Cup profile effect: Good taste balance, acidity was still simple but not sour, texture smoother but the flavour still to flat. No smoky notes anymore, aftertaste sometimes bit dry - depends on the coffee. Coffee with lower density - sometimes bit earthy and dusty.

What to improve: Longer development time; up to 70 seconds. Lower drop temperature for low-density coffee. Small power reduction during the first crack as an option.

5th profile: Longer development time; 65 to 70 seconds. Difference of drop temperature for different green beans: 145°C for low-density beans; 165°C for high-density beans; 155°C as a starting point for all green coffee.

The effect on profile: The whole profile was stable and easy to repeat. Better control on ROR during the first crack.

Cup profile effect: Best taste balance in each cup. Way better quality of acidity. Rich flavour. Aftertaste finally not dry, but long and smooth.

What to improve: Try to put this profile into an environment-temperature mode. Always check the dropping temperature very carefully. Be very consistent between roasts, to have best possible temperature and power control during the routine.

Detailed data of the final, 5th power profile:

RPM: 65

Development time: 60 to 70 seconds.

Drop temperature:

155°C: Starting temperature for all green coffee.

145°C: Good for most of low-density green coffee.

165°C: Good for most of high-density green coffee.

Roasting procedure

Warm up the ROEST sample roaster with full power on (fully closed hatch).

If it is the first batch of the day, wait for 15 minutes before the first roast. The machine needs to be warmed up.

Open the hatch and the power will drop to 0 %.

Prepare 50g of the green coffee you would like to roast.

Wait until 70°C of bean temperature with the hatch open, and then close the hatch. The power will go into full power mode; 100 %.

Launch “live preview” on the panel control of your computer screen, and put the coffee into the hopper.

Wait until the bean temperature will be at the level: 145°C, 155°C or 165°C, depending on the density of the green coffee.

Drop the coffee into the drum. The temperature will rise from 6 to 8 degrees in the first 3 seconds, and then it will start to fall.

Wait, the coffee is roasting. The turning point is usually around 30 to 40 seconds after dropping the coffee.

With the coffee I was using, the first crack was usually between 200-206°C at about 5:00- 5:30 minutes.

Reduce power right after first crack, this is optional for high-density beans. (This step can be automated on the ROEST sample roaster).

Roast with minimum 60 seconds of development time. I would recommend trying from 60 to 70 seconds, depending on your green coffee.

Usually, the end bean temperature is between 203 to 210°C, and the environmental temperature between 220 to 225°C.

Drop the coffee and cool it down for 3 minutes. (Simultaneously, you can start the next step).

Open the hatch to cool down the ROEST sampler roaster to 70°C before you can start the roasting process again.

In the end, you can take the reading from the power profile and create temperature-based profile based on the power profile to make it easier and repeatable.

Note from ROEST team:

This detailed report should serve as an inspiration for you when creating new profiles. Different versions of ROEST behave differently. You might need to adjust parameters accordingly.

For questions regarding to this article you can contact Blazej directly: