Introducing a new feature: Inlet Temperature Sensor

We have learned that power profile is a favorite option of our customers, but it comes with some challenges. Changing room temperature and voltage fluctuation can impact the roasting and the final cup, making it harder to get consistent results and to share power profiles. We first tried to persuade our customers to rather use air temperature profiles, but they had some strong arguments so we decided to develop a better alternative.

After interesting discussions with Scott Rao and Luca Costanzo, we revisited the idea of implementing an Inlet temperature sensor based on the new inlet temperature sensors we have developed for P2000. The inlet temperature sensor is a prominent feature in the roasting community and several roasters worldwide use it. It is a great addition and improvement to the way you operate the ROEST.

Inlet profiles to improve power profiles

An inlet temperature sensor monitors the temperature that comes from the heating element and goes into the roasting chamber. It can give significant improvements to the roasting compared to power profiles due to higher precision.

This type of sensor is therefore a good improvement, or in addition, for those who mainly use power profiles when roasting on a ROEST sample roaster. If you use a power profile regularly, you might have experienced variations in voltage that have given different watts and thus different power between your roasting session. By using an inlet temperature sensor you will see that the temperature that goes into the roaster is more stable.

Luca Costanzo explained: “The inlet temperature sensor offers superior control to power profiles because the PID compensates for the different ambient temperatures, whereas the power profiles will only add a certain amount of power to the room temperature air. For example, if you make a power profile on a hot day, and roast exposed to the outside air at night, the power profile may need to be increased to complete the roast properly. An inlet temperature profile will not be affected by changes in room temperature.”

Higher precision, less variations

By using an inlet temperature sensor while roasting, you will notice that you’ll get a roast with fewer variations. This is because the roaster knows precisely the temperature that goes into the roasting chamber, and the sensor tells you how the coffee and other temperature sensors inside the drum react to the given profile.

To get the best, and most accurate results, we recommend using an inlet profile together with between batch protocol profile. Between Batch Protocol profiles (BBP) is to enhance consistency between batches and automate the process to make it easier. This feature will be available as an OTA update in December 2022.

You can manage the ROEST sample roaster with higher precision, which gives you a more stable and better result in the cup at the end. As every coffee behaves differently, an inlet sensor doesn’t get affected by this, in the way that air temperature profiles will.

“The inlet is the best location for such a sensor because it is before the roasting chamber, so the readings are entirely independent of the coffee in the roasting chamber. To give an example of why this matters, if you use an air temperature profile to roast a bean that is particularly prone to "crash" (eg. washed Kenyan) and switch to one that is particularly prone to flick (eg. anaerobic naturals), you don't know the extent to which the air temperature profile that you settled on for the Kenyan coffee reflected the tendency of that coffee to crash, which makes it harder to know to what extent you need to adapt it for the flicky coffee. This is because the air temperature probe is located on the other side of the roasting coffee from the hot air inlet.” - Luca Costanzo

Roast up to 200 grams of coffee

Since the inlet temperature sensor doesn’t get affected by the amount of coffee beans in the drum, we have tested it with a 200 grams batch, with very good and stable results. This is an increase of 100 grams from what we recommend with other profiles. This means that with an inlet temperature sensor you can roast bigger batches of coffee, without compromising the quality of the result.

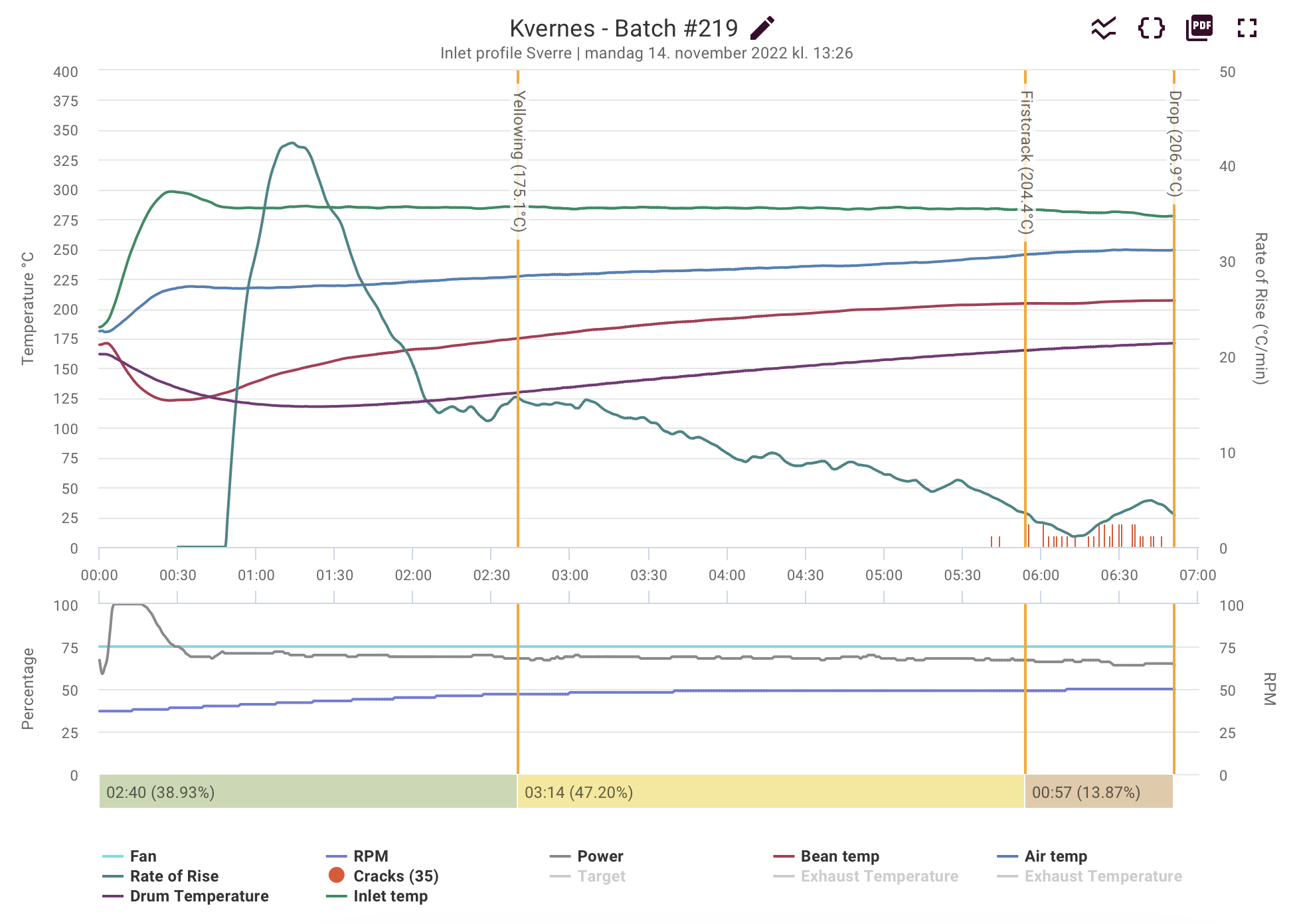

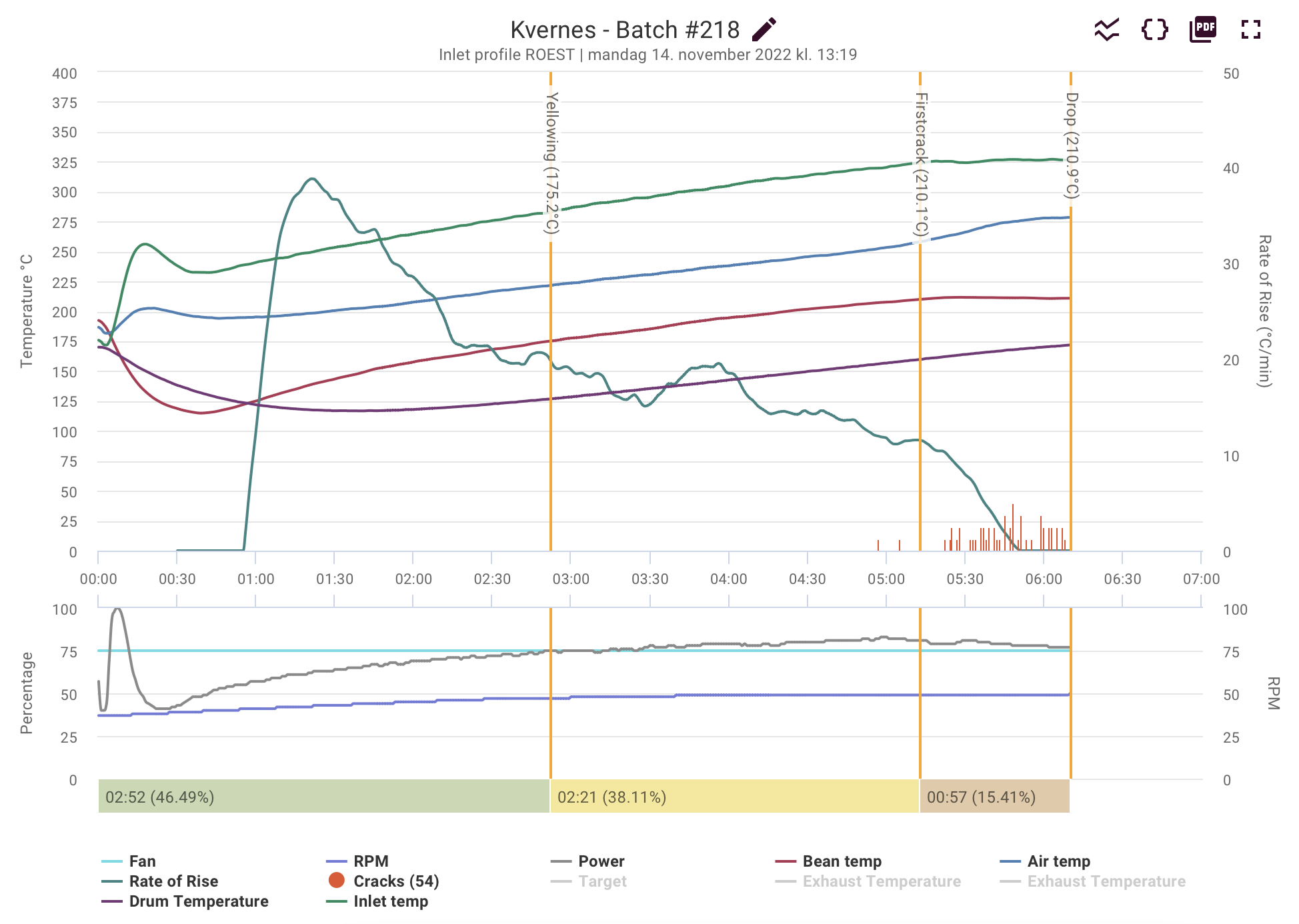

An Inlet Temperature profile with 200 grams coffee. As you can see, the RoR is more stable with 200g batches.

What about air temperature profiles?

The advantage of air temperature profiles is that it takes into account the heat in the system so between batch protocols are not so important. This is therefore still our recommended profile for fast and efficient sample roasting up to 120grams.

Note: Since 2024 the Inlet temperature sensor is a standard feature for all ROEST sample roasters (including legacy model S100 sold since 2024, the new S200, L200 Plus and L200 Ultra)

Enjoyed this? Then check out our article; Roasting coffee for research.