L200 Plus

The professional standard in sample roasting

Premium sample roaster for labs and quality-focused professionals, combining advanced sensors, automatic first crack detection, and an enhanced between-batch protocol to deliver consistent and reliable results trusted worldwide.

Why L200 Plus

What makes it different from S200 model

Free software that scales

ROEST Connect is a professional roasting management tool for live monitoring, cupping, profiles, inventory, and data analysis.

Free with every ROEST roaster.

Efficiency that frees your team

1.6kg per hour with minimal labor. Take advantage of automation— spend less time roasting and more time cupping. Essential for roasteries or QC labs processing a lot of samples daily.

First Crack Detection

No manual marking or missed event. No variability. Each coffee reaches its full flavor potential with consistent development time—regardless of who's roasting.

Complete sensor suite

Five temperature sensors (air, bean, inlet, drum, exhaust) deliver the precision and data density needed for confident purchasing decisions, advancing roasting skills or scientific research.

Automated Between-batch protocol

Maintain consistent starting conditions. Switch between batches in one session—each starts identically, delivering the highest roast consistency.

Features and specifications

-

Develop coffee evenly and quickly with no risk of scorching.

-

Can be configured for 230 V, 115 V or 100 V. 1.65 kW, 50–60 Hz.

-

Roast comfortably from 50g to 200g per batch.

-

The wood panel model is 14 kg, and the black aluminum is 16 kg.

-

Compact footprint for ease of use.

Technical specs

-

8 full 200 g batches per hour with the L200 Plus or S200 model.

15 full 200g batch per hour in Counterflow mode with L200 Ultra.

-

7 min per 200 g batch with L200 Plus or the S200 model.

4 min per 200g batch in Counterflow mode with the L200 Ultra.

-

1.6 kg/hour with the L200 Plus or the S200.

3 kg/hour in Counterflow mode with the L200 Ultra.

Efficiency

-

Hands-free roasting with smart profiles that adapt to your beans. Roasting in two steps: charge green beans, collect roasted beans. With the First crack detection, the first crack event is marked automatically, and the roast is finished automatically.

-

You can take over at any time, with precise control over power, airflow, and RPM. Use the trier for visual checks during roasting.

-

Reset the thermal energy of the machine between batches for perfect profile replication.

-

All-new touchscreen interface with roasting info at a glance, more intuitive controls and easier access to the settings and information you need.

Sleek new interface offers more customization to match the roaster’s design aesthetic, with dark or light modes.

-

Redesigned to operate at higher temperatures for longer, and to better withstand power outages.

-

Immediately start roasting the next batch while the previous batch cools.

-

ROEST Connect is more than advanced roasting software—it’s your roasting assistant. Create profiles, follow your roasts live, manage inventory and cuppings, and analyze every detail of your roasting history. Seamless for beginners and powerful for pros, ROEST Connect streamlines workflow and sharpens results at every stage. Free with your ROEST roasters.

-

All new WiFi module for easy connectivity and faster, more stable networking.

-

Start with S200 model and upgrade to the higher model when you are ready. No need to go through complicated hardware installment. Simply purchase feature upgrade and enjoy!

-

Roast batch after batch without a worry.The roaster collects up to 2kg of chaff in the built-in drawer. On the touch screen you will get notified when it is needed to be emptied.

-

Features

Sensors

-

Monitor temperature of the air inside the drum.

-

Fast, responsive BT probe for manual roasting.

Single BT probe in L200 Plus and S200 model.

Dual sensor in the L200 Ultra.

-

Profiles adapt to ambient changes or power supply fluctuations.

-

Get perfect consistency by monitoring the heat in the roaster itself.

-

Monitor outgoing air to track heat absorption by the beans.

-

Automatically mark first crack and end the roast based on development time. Record each crack in your roast logs, for a fuller understanding of how beans behave in the roaster.

Hear from our customers

ROEST helped the Nordic Approach to increase efficiency and save time:

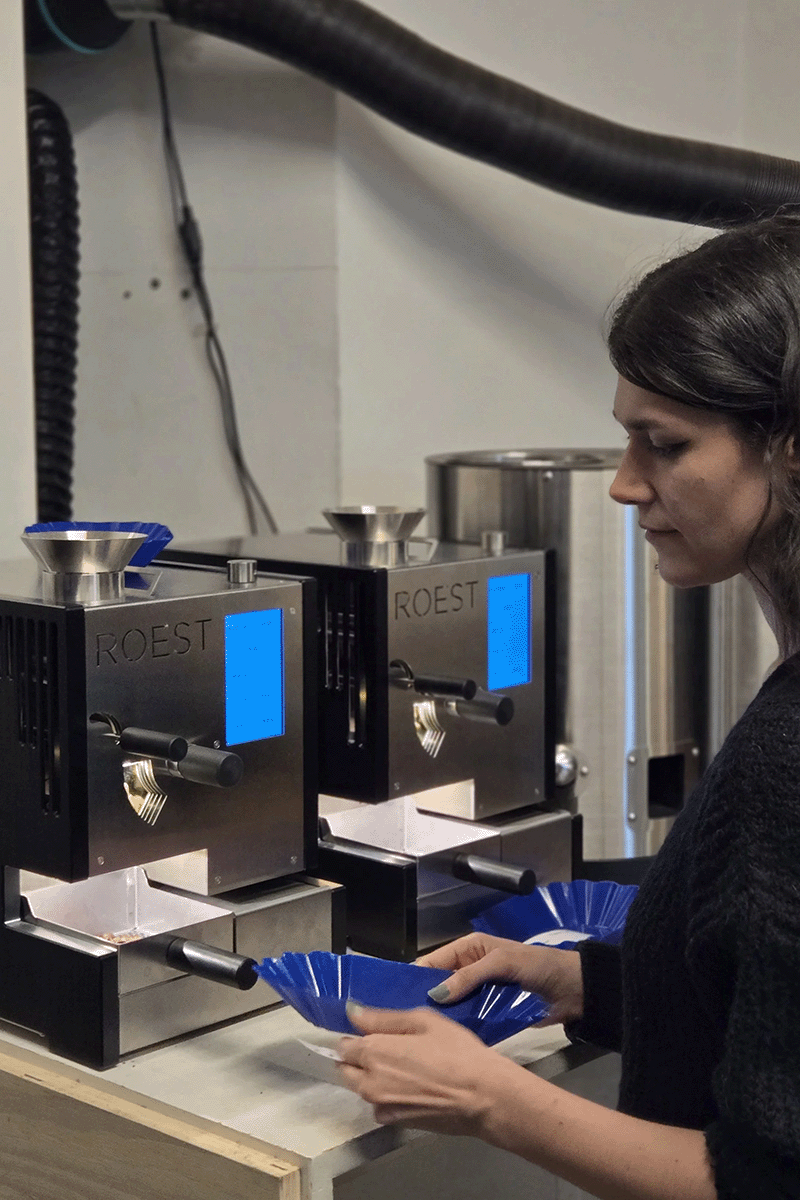

“I quickly realized how nice it was not to be glued to the roaster the whole day. With the ROEST, I could go back and forth, keeping an eye on my roast while registering and measuring incoming green coffee samples, preparing new batches, packing roasted coffee, or even roasting more samples on a second ROEST!”

- Freja Brunn, lab assistant at Nordic Approach

Nordic Approach recently updated the lab to the new L200 Ultra.

Cafe Imports made a smooth transition to ROEST. The result? Improved workflow and effortless control:

“We were nervous about switching during peak season, but the transition was smooth. Within a week, we were back to full speed. ROEST improved our workflow, roast profiles, and efficiency. I can’t imagine the lab without them now.” - Madeleine Avakian-Salvaggio, EU Sensory & Samples Technician

“ROEST gives us more control with less effort. It’s changed the way we work.”

- Ian Fretheim, Director of Sensory Analysis

Read more…

The only roasting assistant you need.

ROEST Connect

From inventory to profiles, data analysis to cupping sessions, everything about your coffee is connected in one seamless platform.

Free with all ROEST roasters.

Between-batch protocol

Consistent roasting, batch after batch.

The automated Between-Batch Protocol (BBP) resets your roaster between batches, ensuring consistent thermal conditions for precise, repeatable results every time.

Maintain control over your roast: avoid overheating, replicate your favorite profiles, and achieve the same development batch after batch. Less guesswork, more precision, and full confidence in every sample.

-

BBP resets the roaster’s thermal energy to a target temperature before charging the next batch. Once the desired conditions are reached, the roaster notifies you on-screen and with sound.

Why it matters:

Consistent results: Every batch starts from the same thermal baseline.

Protect your coffee: Avoid overheating as the roaster accumulates heat over multiple batches.

Optimize profiles: Ideal for Power Profiles and Inlet Temperature Profiles for precise replication.

Save time & stress: No need to manually monitor starting conditions or batch order.

In practice:

Roast multiple experimental coffees with confidence that every batch behaves the same.

Maintain consistency throughout long roasting sessions, whether roasting light, dark, small, or large batches.

Focus on flavor and development, not adjusting for the roaster’s changing thermal state.

First crack detection

Smarter workflow, flawless results.

ROEST is the world’s first sample roaster with automatic First Crack Detection. The roaster identifies the exact moment first crack begins, so development time can be precisely controlled for each batch. This ensures every coffee reaches its full flavor potential—consistently, batch after batch, regardless of who’s roasting.

-

A built-in microphone registers the first crack, distinguishing individual beans from other drum noise. The roaster then automatically tracks development time or applies the ratio set in your profile.

Why it matters:

Consistent development: Each batch develops exactly as intended.

No manual marking: Eliminates human error or missed first crack events.

Maximized flavor: Every coffee reaches its full potential with repeatable precision.

In practice:

Every crack is mapped on the roasting curve automatically.

Development time or ratio triggers batch drop without manual input.

Achieve perfectly developed samples, every session.

Built to grow with you

Start here. Upgrade when you're ready.

The L200 Plus delivers professional-grade roasting with comprehensive thermal monitoring, evolving alongside your ambitions.

Unlock advanced sensors, double your throughput, and gain production-scale features as your operation grows—without replacing your roaster.

-

Today: Start with 5 sensors (air, bean, inlet, drum, exhaust) plus First Crack Detection and Between Batch Protocol—everything you need for professional consistency.

When you're ready: Purchase the Ultra upgrade kit to add features:

Dual bean probe system: Add a second bean temperature sensor for enhanced accuracy and redundancy

Pressure sensor: Monitor and control airflow dynamics with precision

Counterflow mode: Double your output from 1.5kg/h to 3kg/h for production roasting

Why it matters:

Upgradeability means you invest once and build over time. This gives you options:

Grow without disruption: Expand capacity when demand justifies it—not before

Spread the investment: Move from artisan-scale to production-scale as revenue grows

No equipment replacement: The roaster you buy today becomes your production workhorse tomorrow

Professional continuity: Scale your output while maintaining profile consistency

Future-proof: New features become available through hardware and firmware upgrades

In practice: Buy the L200 Plus for your micro-roastery or quality control lab. You're processing 10-20 samples daily with professional-grade sensors and First Crack Detection delivering reliable, consistent results. Six months later, sample volume has doubled and you need faster turnaround. Add the Ultra upgrade to unlock Counterflow mode—now you're roasting 15 batches per hour instead of 8. A year in, you're using the pressure sensor to calibrate profiles across multiple machines or optimize airflow dynamics for delicate microlots. Two years later, you're running a high-volume operation processing 3kg per hour on the same roaster—just upgraded.

One roaster. From lab standard to high-volume operation.

Compare sample roasters

S200 |

L200 Plus |

L200 Ultra |

|

|---|---|---|---|

| Capacity |

Capacity

50 - 200g

|

Capacity

50 - 200g

|

Capacity

50 - 200g

|

| Support and updates |

Support and updates

Free

|

Support and updates

Free

|

Support and updates

Free

|

| Warranty |

Warranty

1 Year

|

Warranty

1 Year

|

Warranty

1 Year

|

| Design option |

Design option

Wood

|

Design option

Wood/Black

|

Design option

Wood/Black

|

| Air temperature |

Air temp

|

Air temp

|

Air temp

|

| Inlet temperature |

Inlet temp

|

Inlet temp

|

Inlet temp

|

| Bean temperature |

Bean temp

|

Bean temp

|

Bean temp

Dual BT

|

| Drum temperature |

Drum temp

-

|

Drum temp

|

Drum temp

|

| Exhaust temperature |

Exhaust temp

-

|

Exhaust temp

|

Exhaust temp

|

| First Crack Detection |

First Crack Detection

-

|

First Crack Detection

|

First Crack Detection

|

| Between Batch Protocol |

Between Batch Protocol

Limited functionality

|

Between Batch Protocol

|

Between Batch Protocol

|

| Pressure sensor |

Pressure sensor

-

|

Pressure sensor

-

|

Pressure sensor

|

| Counterflow mode |

Counterflow mode

-

|

Counterflow mode

-

|

Counterflow mode

|

| Efficiency per hour |

Efficiency per hour

1.5 kg/h

|

Efficiency per hour

1.5 kg/h

|

Efficiency per hour

3 kg/h

|

| TECHNICAL SPECS |

TECHNICAL SPECS

|

TECHNICAL SPECS

|

TECHNICAL SPECS

|

Not sure which model is right for you? Contact our team to get help!

Sample roasters start at €5,290

Explore other models:

Sample roaster

L200 Ultra

Redefining professional sample roasting

The L200 Ultra represents the best of ROEST innovation, with faster roast times, optimized heat transfer, up to 3 kg/h output, and unmatched performance for roasters who demand the best.