Updates on R&D of P2000

It’s been a few years since we started development of the ROEST P2000 – Production Hybrid Roaster. In June 2021 we announced the first information and early bird technical specification - now it’s time for an update!

PROTOTYPE #6

We are currently roasting and testing on prototype #5 in the line, while at the same time finalizing the details of prototype #6 (P06). We aim to have this next prototype in production soon as this will be the version our first pilot customer will use.

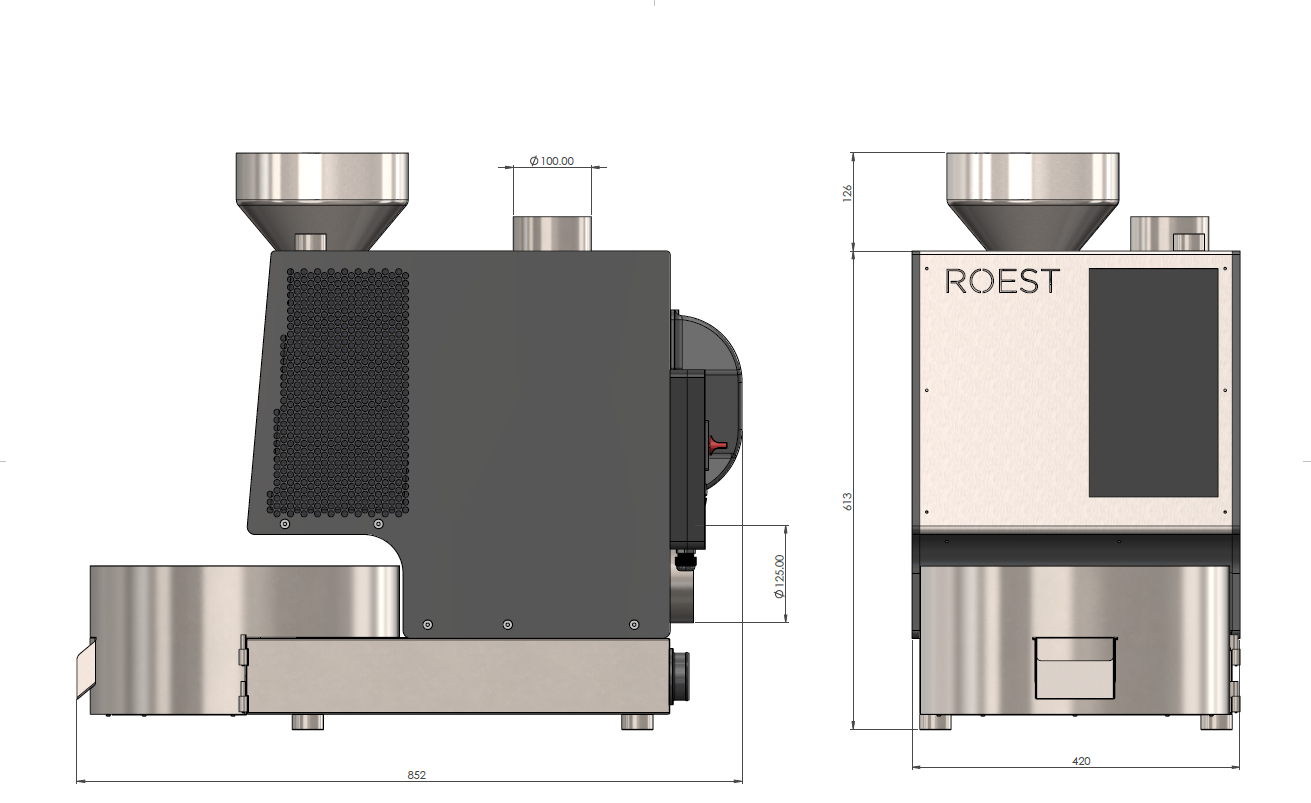

Technical drawings of ROEST P2000 Prototype #6

THE CHALLENGE

What’s the main challenge right now? It’s a blast roasting 1500g batches, but with 2000g the machine feels a little underpowered. Our solution is to increase the drum size on the next version (P06), optimize the internal ventilation system and improve the thermal insulation at critical areas.

We aim to make a roaster with the ideal batch size from 1000g up to 2000g and with enough power to follow your ideal profile with ease. With full power of 4900W, we can get first crack at around 6-7 minutes depending on the coffee - that’s not bad but we would like a bit more flexibility.

MAINTENANCE

This is a critical area for a small production roaster with a huge appetite:

Daily maintenance includes checking three filters if they need cleaning.

Weekly maintenance includes cleaning the internal ventilation with a metal brush using three simple access points.

A few times a year you can remove the top plates of the roaster and the ventilation system and do a deep cleaning

And finally, for the perfectionist, you can split open the entire roasting chamber and polish everything back to perfection.

How does the P2000 work?

ROEST P2000 works very similar to our sample roaster but with an important difference - the air is pushed in through the entire bean mass (in the sample roaster the air is pushed in through the opening in the drum and sucked out).

Why is this important for the P2000? It makes the machine far more energy efficient than its competitors on the market and reduces the need for extensive maintenance of production roasters. A huge benefit is that we can roast faster with lower temperatures.

HOW IS THE P2000 CONTROLLED

We have a whole bunch of sensors, of course! Each heating elements has its dedicated temperature sensor, and we can measure the precise inlet voltage and compensate for it. We have dual temperature (2x BT and 2x ET) sensors inside the roasting chamber, controlling their dedicated heating element making sure we have identical temperatures across the roasting chamber for the most uniform roast possible.

More info about ROEST P2000: It’s time to go bigger (Posted June 9th 2021)