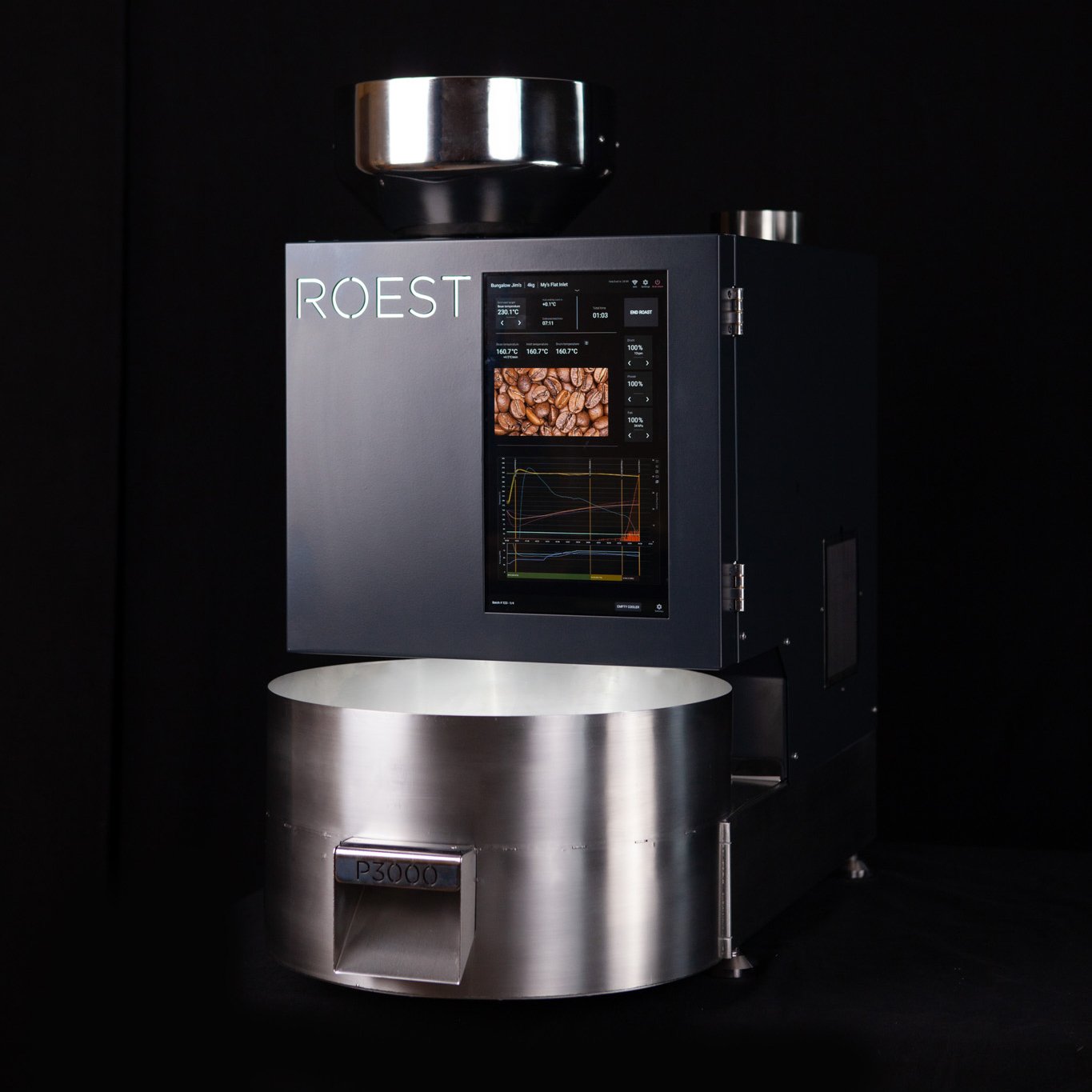

Updates on P3000 - the Production Roaster

We're thrilled to bring you the latest news on the P3000, our next leap in coffee roasting technology.

We're thrilled to bring you the latest news on the P3000, our next leap in coffee roasting technology.

We know that many of you have been waiting for an update on the development of our P3000, and we appreciate your patience. It’s been a year of constant improvements, and today, we are happy to share our latest update, including an estimated timeline for production start, shipments, and scaling of production.

About the P3000

The P3000 is a 3kg user-friendly coffee roaster designed for simplicity and precision. It offers full automation, easy maintenance, and consistent results. It’s a robust coffee roaster, making it ideal for demanding production environments — and easy to learn for new coffee roasters.

The P3000 is a reliable tool for coffee roasting, equipped with advanced sensors to ensure predictable roasting results. Its design focuses on even heat distribution for unparalleled consistency between batches. You won’t be able to taste the difference between two batches of the same coffee roasted with the same profile on the P3000.

Today’s Status

Our team has been constantly working on the P3000 prototype, improving and developing its features. The most significant change since our last update in early 2023 has been the refinement of the P3000’s feature set, as detailed below. It’s all the small things combined that make a great user experience.

As you all know, quality is our biggest priority, and we're dedicating as much time as needed to ensure that the P3000 meets our high standards. Please note that this timeline is an estimate, and changes may occur.

Estimated timeline:

Pilot phase from April 2024

In the pilot phase, a few selected partners will test the P3000 in their own roasteries.Production start September 2024

We are planning on starting production of the P3000 in the autumn. If everything goes as planned, the first units will be shipped out by late autumn of 2024.

Depending on certifications, the P3000 will be shipped to some regions at a later date. More information about this will follow.Scaling of production during 2025

All of our roasters are being produced in Oslo, Norway, and we will begin scaling up our production during 2025.

UPDATED TECHNICAL INFORMATION

Power requirements

We will offer the machine in two versions:

single-phase 230v 32A (7.1kW)

three-phase 400v 16A (9.3kW)

The main difference between them is the heating elements rating and how the machine is wired/configured. It’s possible to re-configure the machine between the two versions.

With the highest-rated version, a full batch size can reach the first crack in 5 minutes.

UPDATES ON THE ADD-ON UNITS

Electric afterburner

We have a functional prototype of the smoke reduction system, and a more refined version is in development. As the capacity of our machine has increased, the power consumption of our afterburner has increased. Our goal is to be able to effectively reduce visible smoke and odor from the roasting process with the power accessible from a single 16A, 230V socket. Easy access for service and maintenance is a high priority as always.

Adjustments to the feeding unit

As promised in our last update on the P3000, there will be a custom feeding unit for the machine that can store up to 100 kg of green coffee and automatically vacuum feed it to the roaster based on your profile weight. The prototype unit is working, and we have a new, improved design ready for pre-production in the coming months.

SENSOR UPDATE

The P3000 collects a lot of data during roasting, and we are constantly looking for ways to improve. For coffee roasting, temperature is still the most fundamental parameter to have control over. It’s no secret that we have added a lot of sensors to the P3000.

Bean temperature

There are two different types of BT sensors. One is super-fast and accurate. The other is stable over time and super accurate. Combining these two sensors, we get the most accurate BT reading possible. We are adding one of each sensor to each side of our symmetrical roasting chamber and giving the user the average of all four sensors.

To achieve the accuracy we are looking for we are developing a calibration chamber to calibrate each bean temperature sensor in house.

Drum temperature

An average of three sensors measures the surface temperature of the roasting chamber drum, located at optimal points along the drum and combining two different types of sensor for the highest accuracy and stability over time.

We can see that the drum temperature stabilizes after an appropriate heat-up or a few batches of coffee. It then follows the coffee roasting process cycle without overheating throughout the day.

Inlet temperature

Having control of the heat going into the roasting chamber is critical for a precision tool like P3000. For an even heat distribution, we are using three heating elements in a row. These are located outside the roasting

chamber, with a pre-mixing chamber for the cold incoming air and a pre-mixing chamber for the heated air going into the roasting chamber (through holes in the drum wall). To control the temperature precisely, each heating element has two custom sensors arranged in opposite locations. This grid of six sensors and an optimised PID ensures the inlet temperature follows your profile exactly.

First crack

First Crack detection in the P3000 proved a challenge as the roasting chamber has a positive pressure inside. We have overcome this problem, and are fine-tuning the algorithm to work across batch sizes and coffees. Development and deployment of more advanced models has been made possible by our integration of OTA (over the air) updates for the first crack module.

Camera

The P3000 integrates a bean camera which displays real-time images of the beans in the drum, replacing a traditional trier. In order to achieve maximum consistency across batches it is essential to remove the destabilising effect of triers on the roasting system. Camera integration is the basis for a suite of future tools to aid decision making, and eventually influence the control system. Colour tracking, the first feature which will be released, gives an indication of the rate of colour change indicative of the velocity of the roast.

As we gear up for the pilot phase and begin planning for production, we remain focused on quality and innovation. Stay tuned for more developments, and thank you for joining us on this journey.

Remember to sign up for our waiting list if you are interested in our P3000 roasting machine!

Roasting Strategies with BT/IT Profiles: What You Need to Know

In this post, we’ll share some tips on optimizing your profile, explain why BT/IT profiles are so powerful — and set you up with some sample profiles to start your journey. To kickstart your journey with creating your own BT/IT profiles, we asked some of our early adopters to share what they’ve learned over the last few months of roasting with the new profile type.

Earlier this year, we announced a new way to control your ROEST: the Bean/Inlet Temperature (BT/IT) profile. If you’ve been wondering how to get the most out of this new feature, then help is at hand!

We are releasing three brand-new resources today to help you get started with the new profile type. Over on our YouTube channel you’ll find an in-depth video all about BT/IT profiles from coffee-roasting expert Christopher Feran. On our support portal, we’ve published a step-by-step guide to designing and troubleshooting your profile. And finally, in this post, we’ll share some tips on optimising your profile, explain why BT/IT profiles are so powerful — and set you up with some sample profiles to start your journey.

BT/IT profiles are only available on machines equipped with an inlet temperature sensor — but if you haven’t upgraded your machine yet, you can use BT/Power profiles in a very similar way.

Expert insights on BT/IT profiles

To kickstart your journey with creating your own BT/IT profiles, we asked some of our early adopters to share what they’ve learned over the last few months of roasting with the new profile type.

Christopher Feran is a roasting consultant and green coffee buyer, based in Cleveland, Ohio, where he is busy establishing a new roastery called Aviary. He was one of the first to embrace the new profile type, and the BT/IT profiles that he has created have rapidly spread throughout the ROEST community.

In his video, Christopher explains why he prefers roasting with BT/IT profiles, and shares his tips to help new users get the most out of these profiles.

The BT/IT profile enables your ROEST to automatically adjust the heat input based not on the roast time, but instead based on how far the beans have progressed in their roast.

This is similar to how an expert roaster traditionally controls the profile — by watching the bean temperature closely, and turning down the heat as the beans get closer and closer to the target temperature.

“This is how I actually approach roasting in a production environment,” Christopher says. “As a production roaster, we approach our adjustments to the roast based on what the bean is actually experiencing — in other words, we’re not trying to achieve a certain bean temperature, we’re making decisions based on the bean temperature.”

For this reason, the BT/IT profile is hands-down the most consistent way to roast your coffee. Even if the beans behave differently, your roast curve can adapt to them to give you the perfect result every time. “This is the type of profile that I use all the time,” Christopher adds.

Tips for designing your profile

Controlling your profile by temperature, instead of time, calls for a new approach when designing your profile. It can be hard to know where to start — we are so used to seeing profiles controlled by time, that designing a profile based on BT might feel like trying to think in four dimensions! But with the right strategy, creating a BT/IT profile doesn’t have to be difficult.

The easiest way to get started with BT/IT profiles, Christopher suggests, is to base your profile on an existing roast curve. Either choose a previous roast that you were happy with, or roast a batch in manual mode. Once you have established the basic shape of the roast curve you want to follow, you can use that data to build your profile. You can find a step-by-step guide on how to follow this approach in our guide to using BT/IT profiles on our support pages.

Christopher Feran’s ROEST in action. The BT/IT profile allows the ROEST to adapt automatically to the beans it roasts.

“Find a result that was successful for you,” Christopher says. “Observe the values for power or inlet at a given bean temperature, plot those against each other and build a profile that way.”

Meanwhile up in Montreal, Thibaut Paggen, the Managing Director of Apex Coffee Imports, has been using a similar strategy. “We roasted samples using a power profile and switching to manual mode. We started translating some of the best roast logs into a series of BT/IT profiles, and have been improving those since,” he says.

Apex Coffee’s BT/IT profile gradually reduces the heat input as the coffee approaches first crack — no matter how fast the coffee gets there.

Once you have a baseline profile in place, it becomes much easier to understand how the profile controls the roast. “The most challenging part was to change our traditional roaster’s mindset about how to approach a roasting curve,” Thibaut explains. “Building profiles with temperature on both axes requires a little bit of brain gymnastics. But once you understand the relationship between both axes, it becomes almost self-evident and easy to manipulate.”

Using BT/IT for consistent roasting

As a green coffee importer, Thibaut’s team has to roast dozens of different coffee samples every day. BT/IT profiles are adaptable, which makes them the best way to approach a new coffee, he finds — but even so, one size does not fit all. “We have a series of 4–5 core BT/IT profiles crafted around density, moisture, water activity, and screen size measurements,” he says.

Christopher follows a similar approach, using different profiles depending on the processing method and moisture content of the bean. “Different coffees need different applications of heat, particularly before yellowing, at the start of the roast, when you’re working to drive that inner development,” he says. “Higher water activity coffees, and naturally processed coffees, will require higher energy at the start of the roast.”

If you don’t want to set up multiple profiles, another option is to use the same profile for all coffees, but to adjust the charge temperature depending on the coffee, Christopher suggests. This is an easy way to apply a little extra heat at the beginning of the roast for coffees that need it, such as those with a high moisture content.

Roasting with a BT/IT profile, of course, relies on having an accurate bean temperature reading. The bean temperature probe works best when it is fully covered with beans — which happens at batch sizes of 125 grams or more. With batches smaller than this, the bean temperature reading starts to be influenced by the surrounding air, Christopher points out. “It can be done at 100g, but you should know that you’re getting a lot more air in that thermocouple reading.”

Try BT/IT profiles for yourself

If you’re looking for a detailed guide on using BT/IT profiles, then head over to the user’s guide on our support pages. There, you’ll find guidance on when to use BT/IT profiles, and when another type of profile is a better option. We also give you some troubleshooting tips for developing your own profile.

Christopher designed his profile with specific settings in mind. In particular, he adjusts the fan settings to control the drum pressure in his Roest.

If you just want to jump in and get started, however, then Christopher Feran has kindly agreed to share his standard BT/IT profile (named CF base profile) to get you started —you can find it on our Profile Library. If you use this profile, be aware that it is designed for Christopher’s specific machine, which has a few very specific settings, so you will need to make some adjustments to make it suit your own needs. “It’ll take some experimentation for you to figure out what works best for you,” he says.

Christopher’s roasting log of the shared profile to help you understand how the profile behaves on his ROEST.

“I do recommend you play with these profiles, you’ll find they’re extremely consistent,” Christopher adds. “It really is setting you up for much more success in evaluating your samples.”

Adapting to the beans: introducing Bean/Inlet Temperature profiles

Our sample roasters perform the same way each and every time that you roast - but sometimes, the green beans have other ideas. Every batch of beans is slightly different, even if you pull them from the same bag.

The solution is a roast profile that adapts itself to how the beans respond by adjusting the amount of heat according to what stage of the roast the beans have reached. You can do this with Bean Temperature/Inlet Temperature (BT/IT) profiles, a new feature included in our latest firmware update.

Note: the firmware update with this new feature is due for release later this month

Our ambition at Roest is to make consistent and repeatable roasting as easy as possible. We know you can rely on our sample roasters to perform the same way each and every time that you roast - but sometimes, the green beans have other ideas.

Every batch of beans is slightly different, even if you pull them from the same bag. And the results can be even less predictable if you’re roasting a boxful of different samples back to back.

Green beans come in all shapes and sizes. Our BT/IT profiles can help you adapt.

The solution is a roast profile that adapts itself to how the beans respond by adjusting the amount of heat according to what stage of the roast the beans have reached. You can do this with Bean Temperature/Inlet Temperature (BT/IT) profiles, a new feature coming soon in our next firmware update.

We started work on this new profiling system based on feedback from Scott Rao and David Stallings, COO and Director of Sourcing at Osito. They pointed out that on a commercial roaster, they would change the gas settings based on what temperature the beans have reached rather than how long the beans have been in the drum. Why shouldn’t our sample roaster be able to do the same?

In a blog post last year, Scott described our BT/IT profiles as ‘the last piece of the puzzle’ in creating consistent and high-quality roasts. We’re very proud to finally be making this feature available to all of our customers in the next firmware update, due for release in August 2023.

What is a BT/IT profile?

Until now, all our roast profiles have been based on time. Each change in the profile happens a fixed number of seconds after the roast begins, no matter what is happening in the bean pile. With a BT/IT profile, each change in the profile happens when the beans reach a certain temperature, instead of happening at a fixed time.

Creating a BT/IT profile. Each setpoint is triggered when the beans reach a certain temperature.

Designing a BT/IT profile is simple. It works the same way as creating any other profile on the Roest, except that the setpoints are based on bean temperature, instead of time. You can learn more about how to create your own profiles in our guide to the Roest web portal.

In between each setpoint, the Roest smoothly adjusts the inlet temperature as the bean temperature changes. This enables you to apply precisely the right amount of heat to the beans the whole way through the roast.

Roasting with a BT/IT profile. The inlet temperature (green) varies smoothly between each setpoint, giving you control over the entire roast curve with just a few setpoints.

What are the advantages of BT/IT profiles?

If you are using the inlet temperature sensor on your Roest, then you already know the benefits of profiling a roast based on inlet temperature. And if you don’t, take a look at our blog post all about the inlet temperature probe.

Adding BT/IT profiling takes that a step further, giving you more control and making your roasts even more consistent. “Using BT/IT doesn't necessarily yield better roasts, but it offers better control and long-term consistency than any other profiling system I know,” Scott says.

Alongside Scott and David, some of the world’s best roasters have been beta-testing this feature for us over the past few months. We asked them to share their experiences with the new profiles.

The number one benefit that they all mentioned was the improved consistency the new feature offers. Jaroslav Tuček, founder of Doubleshot in Prague, relied on the Roest’s ability to replicate a profile exactly when roasting their coffee for Kamila Chobotova at the World Brewers’ Cup. “We had to consistently roast 5–10 batches to achieve the desired volume of 1–2 kg,” Jaroslav says. “It was amazing to see the differences in weight loss, colour and temperature fall in a minimal range for those 5-10 batches.”

Scott Rao’s BT/IT profiles, posted on his blog, showcase just how consistent this type of profile can be.

Wille Yli-Luoma, co-founder of Heart in Portland, agrees, saying: “[BT/IT] is really the only way you should control a roast to get the most consistency.”

Wille also appreciated how easy it was to get great results with the new firmware. “It’s very similar to our production roaster, but even easier to use.”

“We were able to create profiles that were close to what we wanted within a few tries — and sometimes on the first try. This program is the easiest and most intuitive of all roasting softwares out there.”

The other key advantage of BT/IT profiles for many roasters is that it replicates the way that they operate their commercial machines. This makes the Roest an invaluable tool for developing new profiles on production roasters. While you can’t translate a profile directly from a sample roaster to a production machine, the Roest can help you predict how a coffee will behave during roasting.

Roest machines can speed up the process of developing roast profiles for larger roasters.

“We discover the potential of a coffee by using the ROEST, and then strive to achieve the same on our production machine,” Yara explains. “You cannot compare the exact values between those two machines, but you can compare the final results and the way to achieve it.”

How to get started with BT/IT profiling

The new profiles are being released as part of an automatic firmware update — the machine will update by itself when you connect it to the internet via the WiFi connection. Once the firmware is updated, you’ll see the new options added when creating profiles in your web portal — or you could just choose an existing profile from the public profile library.

Some users report that BT/IT profiles are most effective for larger batches of 120 grams or above — but try them for yourself, and discuss your results with other users on our forum.

Of course, you can only use BT/IT profiles if you already have an inlet temperature probe installed. If your Roest doesn’t have an inlet temperature probe yet, you can install it yourself or, if you prefer, we can upgrade your roaster for you. If you need help, or you’re looking for a quote, then get in touch!

Important note: Only models with production numbers starting P11_ and higher can upgrade to the inlet sensor and use BT/IT profiles. You can check the production number on the sticker behind the magnetic plate on the front of your roaster.