Adrian Berg's WBC journey

Adrian Berg, coffee roaster and two-time Norwegian Barista Champion, got the exciting opportunity to participate in the World Barista Championship 2021 (WBC). He was determined to roast his own competition coffee, and luckily for us, decided to use ROEST Sample Roaster on his WBC journey! We caught up with Adrian to find out how he prepared and built his final WBC-espresso profile with the help of ROEST.

Adrian Berg, coffee roaster and two-time Norwegian Barista Champion, got the exciting opportunity to participate in the World Barista Championship 2021 (WBC). He was determined to roast his own competition coffee, and luckily for us, decided to use ROEST Sample Roaster on his WBC journey!

We caught up with Adrian to find out how he prepared and built his final WBC-espresso profile with the help of ROEST:

Hello, my name is Adrian and I am the 2019 and 2020 Norwegian Barista Champion. I’ve been a competition barista for many years, but it was only after I started roasting my own coffee that I was able to win. For my 2020 WBC routine I knew I wanted to continue to roast the coffee myself, but I was also worried about committing large amounts of expensive coffee to trial roasting. So I reached out to ROEST who were super-kind to loan me one of their sample roasters.

Selecting Competition Coffee

My routine was built around the concept that flavour notes are not good enough tools when it comes to communicating flavour to customers. In order to make that point, I knew that I needed coffee with a lot of clarity that would be easy to describe so that I could deconstruct and explore how we can use flavour notes differently. Patrik Rolf at April Coffee Copenhagen helped me source my competition coffee and I ended up picking two: a gesha and an SL28 from Volcán Azul in Costa Rica, both anaerobic fermented and incredibly crisp and bright.

Trial Roasting

Having the ROEST available to trial roast the coffee was incredibly useful. I spoke with Matt Winton (who went on to win the World Brewers Cup!) about building a profile for espresso on the ROEST and after a lot of trial with a placeholder coffee I stumbled upon Wojtek Bialczak’s air temp profile on the ROEST community forum. I used that as my base profile to play around with the settings and find the right roast level.

Challenge of Espresso

“The biggest challenge with roasting for espresso on a sample roaster is that espresso generally needs to have higher solubility to work well, which requires longer roast times or a darker roast.”

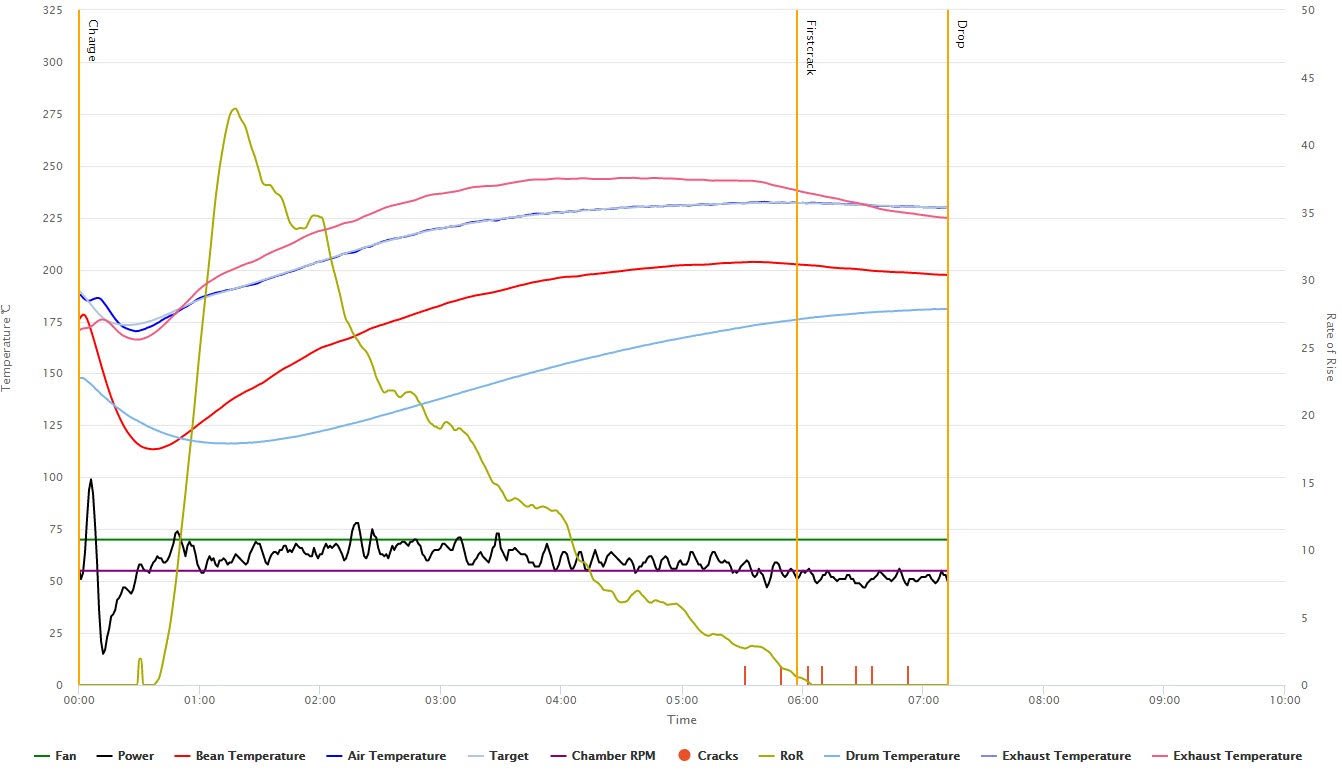

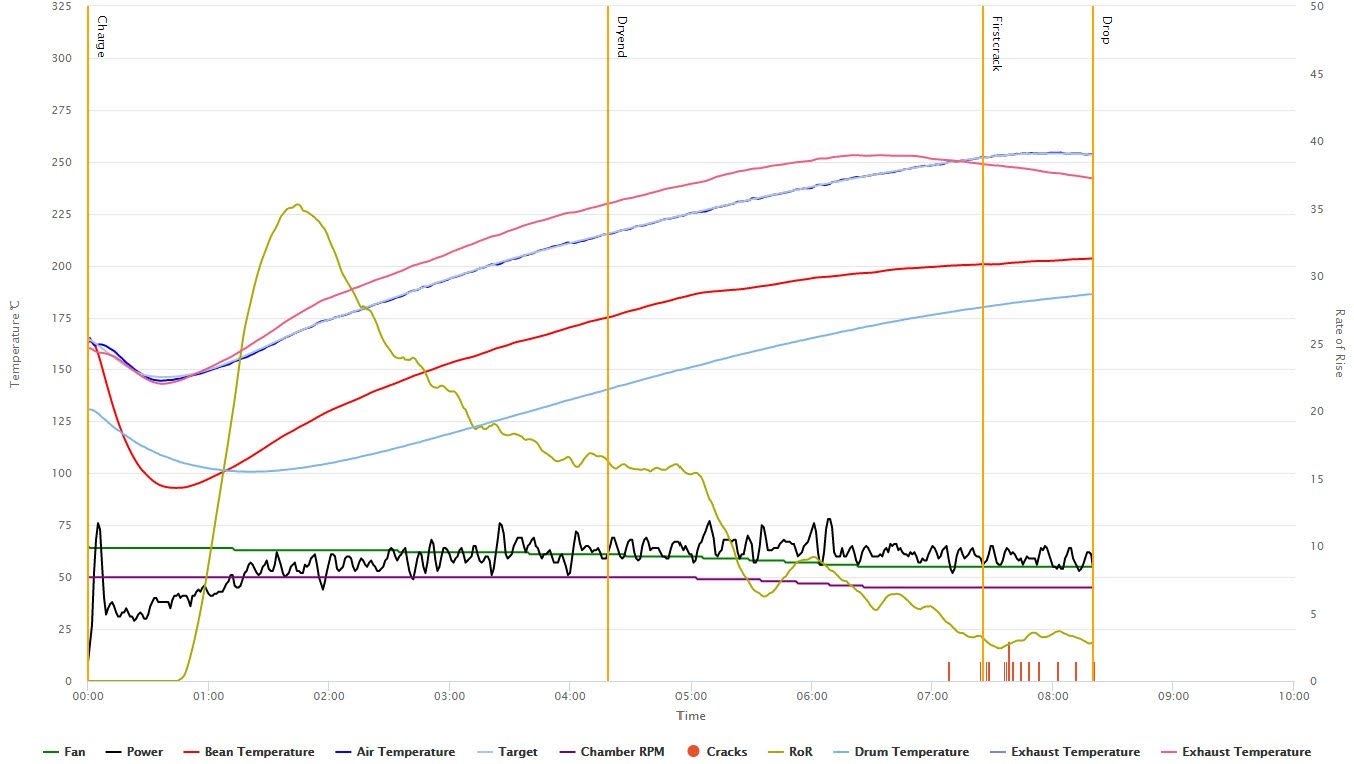

Most profiles I found for the ROEST were anywhere from 4 to 6 minutes long, much too short for espresso. Using Wojtek’s air temp profile I was able to get roasts that were 8-9 minutes long. It started with a high charge temp, a short soaking period, then ramping the air temp back up before gradually bringing it down throughout the roast. This gave a very stable declining rate of rise and stretched the roast time beyond the six-minute mark.

(Development) Time is Key

The second challenge was finding the right development time. Most profiles I came across had a development time between 40 to 60 seconds. For an 8 minute roast 60 seconds is only a 12.5% development time ratio, which isn’t a lot for espresso. Since the air temp profile gave a steadily declining RoR the increase in bean temperature after first crack wasn’t that big either, so the coffee came out quite light with a very high and sharp acidity as espresso. The solution was to lower the air temperature after a little bit more from yellowing to increase the total roast time to 9 minutes and give the coffee a 90 second development time, increasing the DTR to 16%.

Saving Time with ROEST

If this all starts to sound a bit too technical, let’s just say it balanced out the coffee, made it more soluble and made a very nice espresso.

“For consistency I roasted several 100g batches back to back on the ROEST and blended them together to form a single batch. That was probably what I enjoyed the most about working with the ROEST.”

Once I was happy with the profile, recreating it was completely automatic with Auto First Crack Detection and playback of the profile. That freed up my hands and brain to continue working on my presentation and concept.

Want to know more about Adrian’s WBC process? Check out our latest video!

Reflections

I’m incredibly thankful to ROEST for the opportunity to work with their roaster. It helped me reach a final roast profile much quicker and with much less green coffee wastage, saving me time and money, both currencies that are incredibly valuable when preparing for a World Championship. I only took 25th place but I learned a lot from the experience. Seeing the passion, skill and dedication of the champions who went on to the semi-finals and finals was incredibly motivating. I look forward to the next time I’ll be in a coffee competition and continue to grow as a barista, roaster and person. Thank you, that’s my time!

Thank you, Adrian, for sharing your knowledge with the ROEST community. We are honored to have been a part of your WBC journey, and we’ll be rooting for you in all your future endeavors!

Text and photography by Adrian Berg

Want to know more about how ROEST can be used in competitions? Wojtek Bialczak participated in the World Barista Championship in 2019, and used ROEST sample roaster! He shared how it helped him and how it could help you:

ROEST and Condesa Co.Lab: A tale of two coffee labs

In mid-2019, specialty coffee importer Condesa Co.Lab celebrated its seventh birthday. Managing Director Stephen Bannister says that after those seven years of growth, the team felt established and successful. He said that even then, the team was optimistic about the future – however, he also acknowledges that they weren’t entirely prepared for what it would bring.

Harry McAuley, Trade and Quality Assurance, getting ready for a cupping session.

In mid-2019, specialty coffee importer Condesa Co.Lab celebrated its seventh birthday. Managing Director Stephen Bannister says that after those seven years of growth, the team felt established and successful.

He said that even then, the team was optimistic about the future – however, he also acknowledges that they weren’t entirely prepared for what it would bring.

Stephen says that as a result, the team has come to realise they need time and space to grow. He tells me that a healthy, happy team can deliver better quality and better service for our partners, and that requires a certain amount of expansion.

In this post, he explains more about what that expansion entails, and the journey that led Condesa to partner with us here at ROEST. Read on to learn more.

“We knew that we needed to work smarter, not harder, for the benefit of ourselves and our partners”

Feeling stretched

Our lab served us well for more than seven years, and in mid-2019, we brought in a new machine to accompany our trusty common gas roaster. However, as our business continued to grow, sample roasting became more demanding and time consuming.

We certainly benefited from a little bit of respite when the second machine arrived, but even with four barrels, there were still days when the team felt chained to the roaster.

Since 2013, on average, we have roasted around 3,000 samples per year. In total, that’s about 26,000 minutes or 433 hours, which is nearly 11 working weeks. That’s a fifth of the working year spent on roasting alone.

As you can imagine, we take quality control very seriously here at Co.Lab. We cup everything multiple times before any coffee is delivered to a partner. Quality is our job, and we do not shy away from it. But we felt that something needed to change.

Condesa Co.Lab ensures quality by cupping everything multiple times before any coffee is delivered to a partner.

Recognising the need for change

To start, we wanted to look for new premises for our Co.Lab, with the intention of securing a new site by the end of 2019. When 2020 arrived, however, everything changed.

For most of us, it was a year to forget. It was a complicated and unwelcome time, but despite the difficulties, there was also opportunity. The unprecedented challenges of the year forced Co.Lab to change for the better.

All across the coffee industry, we apply the same SCA and CQI processes to grade and review coffee. The problem with the pandemic was that we were unable to travel, unable to cup, and unable to communicate in perfect. As hard as you might try, you simply can’t do quality control over the internet.

As the first wave of the pandemic passed, we took a moment to breathe and reflect. This gave us some much needed perspective. It was then that we knew we needed to take our new lab in a different direction.

We resolved to empower the people in our team by supporting them to embrace technology. We knew that we needed to work smarter, not harder, for the benefit of ourselves and our partners.

As we arrived at the end of 2020, we knew we had no other option but to adapt. The world was not the same, and it would take time to move forward.

One of the three ROESTS owned by Co.Lab, making sure the team is given enough time to prepare samples that will meet their partners expectations.

ROEST x Condesa Co.Lab

Driving this kind of positive change can be easier said than done. But as we moved forward, we made sure our focus was on one thing above all else: creating more time for our team.

Time is, after all, the most important thing that we can give our coffee lab teams to support them. It ensures all the skills we have learned cupping can be put into the next round of samples to make sure they meet our expectations.

Ultimately, time ensures that the samples we send to our partners meet their expectations. At the same time, time also lets us discuss and align the analysis of a coffee with those partners, allowing us to build trust.

Creating time is one of Co.Lab's key purposes, both for our partners and our own team. To that end, we have welcomed three ROEST sample roasters into our lab, all the way from Norway. In true Scandinavian spirit, they are stylish, tidy, always on time, and always ready to give their all for Co.Lab.

Moving to an automated roasting system has enabled us to:

Build a library of producer-consistent profiles

Give better information about roasted samples to partners

Tailor a roast irrespective of variety, process, origin, or density, allowing for clean and transparent roasts with enough development to allow people to assess the coffee and its key characteristics

Share profiles and improve our own learning with transparent dialogue about how coffee is roasted

Monitor roasting from remote locations to improve the quality of the process

Enhance safety protocols with automated batch dropping

Embrace new features to work on incremental improvements for the benefit of all users in the future

Profiles by Condesa Co.Lab - download and give them a go!

Throughout the whole purchase process Condesa receives several samples to continually check the health of each coffee.

Our primary incentive for using this automated roasting system is to improve quality outcomes for our partners. However, as a secondary benefit, our Co.Lab is now a healthier place to work, as our team spends less time roasting.

In turn, this means we can spend more time sourcing and delivering high-quality coffee for our partners.

To share this with the coffee community, the Condesa Co.Lab Coffee Lab in Sydney will be open for roasters to come and work with these incredible ROEST machines. Please get in touch with Eli at qualitylab@condesa.com.au if you’re interested, or just reach out for a chat.

Written by the Condesa Co.Lab team

Photo courtesy of Condesa Co.Lab

Updates on R&D of P2000

It’s been a few years since we started development of the ROEST P2000 – Production Hybrid Roaster. In June 2021 we announced the first information and early bird technical specification - now it’s time for an update! We are currently roasting and testing on prototype #5 in the line, while at the same time finalizing the details of prototype #6 (P06).

It’s been a few years since we started development of the ROEST P2000 – Production Hybrid Roaster. In June 2021 we announced the first information and early bird technical specification - now it’s time for an update!

PROTOTYPE #6

We are currently roasting and testing on prototype #5 in the line, while at the same time finalizing the details of prototype #6 (P06). We aim to have this next prototype in production soon as this will be the version our first pilot customer will use.

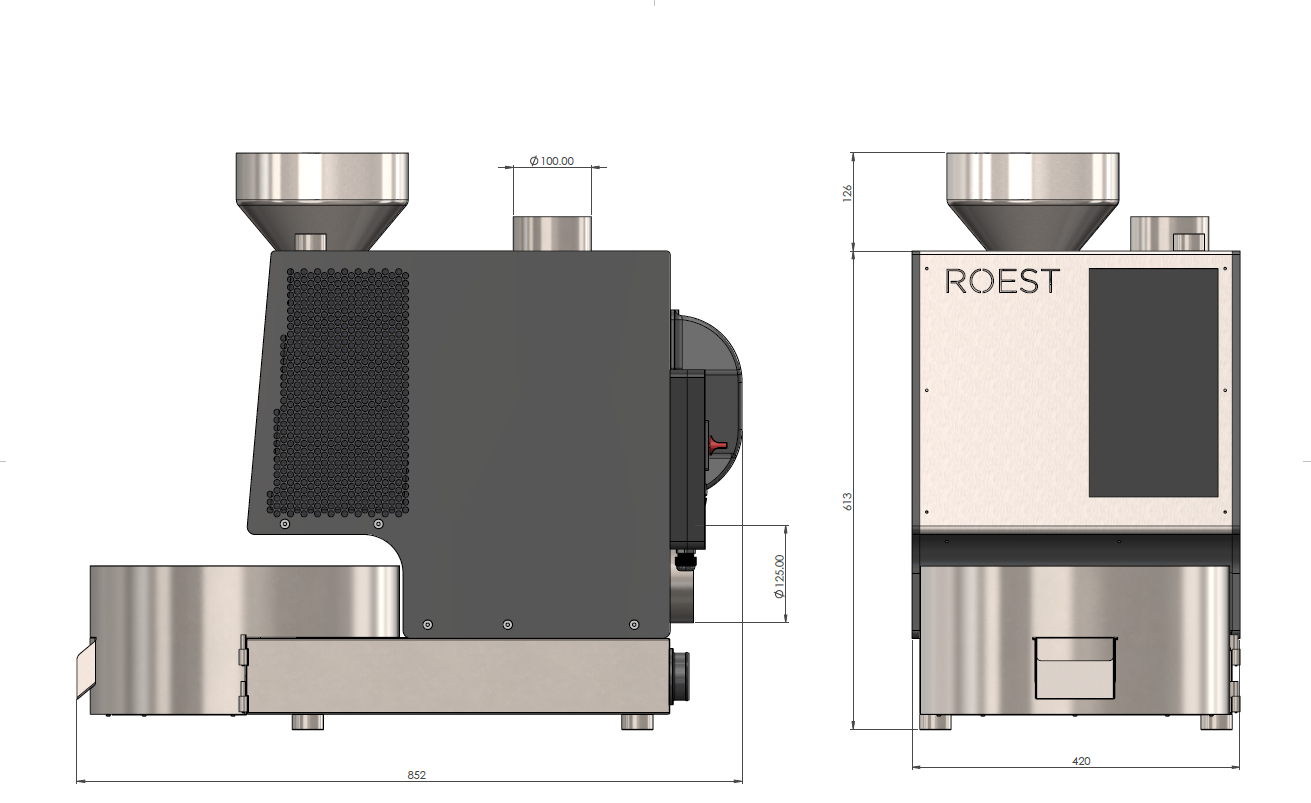

Technical drawings of ROEST P2000 Prototype #6

THE CHALLENGE

What’s the main challenge right now? It’s a blast roasting 1500g batches, but with 2000g the machine feels a little underpowered. Our solution is to increase the drum size on the next version (P06), optimize the internal ventilation system and improve the thermal insulation at critical areas.

We aim to make a roaster with the ideal batch size from 1000g up to 2000g and with enough power to follow your ideal profile with ease. With full power of 4900W, we can get first crack at around 6-7 minutes depending on the coffee - that’s not bad but we would like a bit more flexibility.

MAINTENANCE

This is a critical area for a small production roaster with a huge appetite:

Daily maintenance includes checking three filters if they need cleaning.

Weekly maintenance includes cleaning the internal ventilation with a metal brush using three simple access points.

A few times a year you can remove the top plates of the roaster and the ventilation system and do a deep cleaning

And finally, for the perfectionist, you can split open the entire roasting chamber and polish everything back to perfection.

How does the P2000 work?

ROEST P2000 works very similar to our sample roaster but with an important difference - the air is pushed in through the entire bean mass (in the sample roaster the air is pushed in through the opening in the drum and sucked out).

Why is this important for the P2000? It makes the machine far more energy efficient than its competitors on the market and reduces the need for extensive maintenance of production roasters. A huge benefit is that we can roast faster with lower temperatures.

HOW IS THE P2000 CONTROLLED

We have a whole bunch of sensors, of course! Each heating elements has its dedicated temperature sensor, and we can measure the precise inlet voltage and compensate for it. We have dual temperature (2x BT and 2x ET) sensors inside the roasting chamber, controlling their dedicated heating element making sure we have identical temperatures across the roasting chamber for the most uniform roast possible.

More info about ROEST P2000: It’s time to go bigger (Posted June 9th 2021)