Customer Success Story: Origin Coffee Lab

At Origin Coffee Lab (OCL), Jose Rivera and his team work tirelessly during the peak harvest season to ensure they offer the best quality coffee to their clients. However, with the vast number of coffee samples they need to analyze, sample roast, and cup - time is of the essence. That's where the ROEST sample roaster comes in to help.

At Origin Coffee Lab (OCL), Jose Rivera and his team work tirelessly during the peak harvest season to ensure they offer the best quality coffee to their clients. However, with the vast number of coffee samples, they need to analyze, sample roast, and cup - time is of the essence. That's where the ROEST sample roaster comes in to help.

The view of Origin Coffee Lab farm in Peru.

Costing expertise and quality control

Jose, who had acquired knowledge about the coffee industry while working as Director of Green Coffee in a small roastery in Chicago, knows that to break down the costs of each coffee, he needs to understand how the other side of the industry works. This understanding has helped him to calculate prices more precisely and be more competitive in the market.

To offer high-quality coffee, OCL has a rigorous and exhaustive quality control process in its lab. Jose believes that this sets them apart from other organizations. However, this process can be time-consuming, especially during peak harvest season when they need to analyze, sample roast, and taste many coffee samples during the cupping.

Jose and his team cupping coffee to ensure quality.

Revolutionizing sample roasting and tasting

ROEST sample roaster has made an enormous difference at OCL. A team of 5 tasters and 5 sample roasters can roast up to 9 samples every 15 minutes, significantly reducing the time it takes to roast and taste coffee samples. The sample roasters run non-stop from 8 am to 7 pm, and they can taste up to 1750 cups of coffee a day with its help.

“The workload was so intense that we decided to try ROEST, and the change was spectacular. We have reduced times: what we used to do with six drums of Probat, we now do with three ROESTs.”

Jose is impressed with the sample roaster's performance and says, "I don't think there is a company in the world that gives these roasters as much of a hard time as us." Yet, even with this high performance, the roasters are running smoothly, and the OCL team can rely on them. In addition to reducing time, ROEST has also enabled their team to roast in fully automatic mode, freeing up more time to learn how to taste and analyze coffee and manage the lab. This has helped them to develop professionally in a more efficient way.

A well-equipped coffee lab with ROEST sample roasters.

With the help of the ROEST sample roasters, Origin Coffee Lab can now offer high-quality coffee to its clients while significantly reducing operational time and costs. Their commitment to quality control and investment in modern equipment like ROEST is a testament to their dedication to the specialty coffee industry and their clients.

Interested in the ROEST sample roaster?

Jose Riviera and Origin Coffee Lab is an exclusive distributor of ROEST sample roasters in Peru - find their contact information here.

Liked reading about our customers? Check out our interview with Katja Klein - Founder of Kontext Coffee Company.

Introducing new: Public Profile Library

If you are new to roasting or want to explore other roasting profiles, we have now made it easy for you to download and upload profiles directly from our web portal. We want to create a space where everyone can roast coffee, develop their skill, and share their knowledge about coffee roasting.

Our main goal is to make roasting as fun and easy as possible. Until now, every profile created and shared with other ROEST users has been uploaded to the profile library inside our forum. We have now created another new feature inside the web portal: the public profile library. To make it easy to find and share profiles. All in one place.

ROEST’s new profile library inside the web portal.

Finding the right profile

Roasting coffee is a form of art. Setting the right profile for the right beans can be difficult. When sample roasting, you usually get one chance to roast an unfamiliar coffee, which can be challenging when evaluating the coffee or reaching its full potential.

When creating a new profile inside ROEST Web Portal, you can choose between the three most common:

Air temperature profile

Inlet temperature profile*

Power profile

Different types of profile you can create inside the web portal.

The advanced profiles you can create are:

Bean temperature profile

Bean temperature vs. power input **

Bean temperature vs. inlet temperature**

* for machines with an Inlet sensor

** available in BETA from March 2023

Which one to choose depends on what coffee you are roasting or batch size. Other parameters are also to consider when selecting a roasting profile for your sample roasts.

If you are roasting to evaluate a coffee’s quality, you might want to roast each batch in the same way to compare them fairly. If so, you must find the right profile for your beans and repeatedly repeat that.

If you are roasting for consumption, you might want to explore different profiles to find a style that consumers will enjoy. You can play around with other profiles, parameters, and roasting styles here.

Explore the world of ROESTing profiles

ROEST Web Portal is developed to make roasting easier and more educational and to give you a better understanding of the roasting process. Features inside the web portal are analyzing and comparing roasts, arranging cupping sessions, monitoring your roast in live view, and creating different types of profiles.

If you are new to roasting or want to explore other roasting profiles, we have now made it easy for you to download and upload profiles directly from our web portal. We want to create a space where everyone can roast coffee, develop their skill, and share their knowledge about coffee roasting.

Adding metdadata helps your profile to be searchable for others.

After creating a profile, one of the new things you can do is add metadata. Adding metadata such as description, origin, and the process will make your profile searchable through the filter. Let’s say you want to find a profile suitable for washed coffee from Central America. If metadata is added, a profile with these criteria will be shown. This will make it easier and more helpful to find the right profile you seek.

Share your profile

Within the ROEST community, many experienced roasters have made well-tested and verified profiles. And we know how educational and handy it can be to share different types of profiles with each other.

Every profile created by any ROEST user can now easily be uploaded to the public profile library. We encourage all our customers to upload their profiles to the public profile library so that we can share knowledge and passion between us.

Download as many profiles as you want from our profile library.

When a profile is uploaded and tested by us at ROEST, we can verify that profile, so it gets a badge next to it. All verified profiles have undergone a qualification process so that you know this is trustworthy.

You can also see how many times the profile was downloaded to help you see what is popular in our community. Did you enjoy the profile? Leave a star-rating.

Help us grow the community

Share your profile with other ROEST users to help us grow the community.

The public profile library is on its first version now, and as always, there will be improvements to the feature in the future. Right now, we need your help to fill it up with your favorite ROEST profiles.

How to publish your profile:

Go to the profile you want to share.

Add metadata to help others to search your profile.

Share your profile and add it to the profile library.

Now, let’s start exploring the different ways of roasting coffee together.

Enjoyed this? Check out our articles about our new cupping form inside the web portal or between batch protocol.

S100 Plus or L100 Plus - Finding the right Sample Roaster for you

So you’ve been eyeing the ROEST Sample Roasters for a while and find yourself wondering - should I get S100 Plus or L100 Plus? In this article, we’ll be breaking down information about both roasters and help you make a decision.

So you’ve been eyeing the ROEST Sample Roasters for a while and wondered - should I get S100 Plus or L100 Plus?

Deciding on which sample roaster to purchase can definitely be a confusing task. The models have their own distinctive designs and include both similar and different features. To choose the right one, you must ask yourself what’s more important.

In this article, we’ll break down information about both roasters and help you decide. And should you have any questions, feel free to contact us or read more about ROEST here.

Similarities

We must first look at the similarities to find the right sample roaster for you.

All ROEST Sample Roasters is a combination of two technologies: hot air roasters and conventional open drums - offering the best of both worlds! They have a batch capacity of 50 - 200 grams*, allowing you to experiment with smaller samples and produce less waste. The dual fan system for separate cooling allows you to roast back-to-back with no daily limit. Hence, both sample roasters contribute to a better workflow.

Sounds good so far? Very much. Now let’s move on to the most beloved features available to both S100 Plus and L100 Plus.

*Only S100 Plus and L100 Plus.

First Crack Detection

First Crack Detection is one of our most convenient features in both S100 Plus and L100 Plus.

This feature turns ROEST into a fully automated roaster that ensures each coffee reaches its full flavor potential regardless of skill. How is this possible?

The First Crack detector will identify individual cracks and register the First Crack event.

After the event is recorded, the roaster starts counting down the development stage and automatically releases roasted beans.

“One of the reasons I decided to get a ROEST machine was its automatic First Crack Detection function. This is because First Crack decides not only quality but also consistency.”

- Hidenori Izaki, 2014 Barista Champion

Consistency is essential when it comes to roasting the perfect batch. By collecting FC data, you will better understand what’s happening to the coffee and gain better control over the roast and the flavor profile.

For businesses roasting multiple batches per day, it is also an enormous help to save time, reduce workload and save money - all thanks to full automation with high-quality and consistent roasts. You can rely on automated technology to help you perfect your roasts without much attention and interaction.

Air Temperature

The air temperature measures the environment inside the drum and corresponds to the convective heat energy you have available. Changes to this temperature can affect the desired qualities of a roast, so predicting its behavior can help keep the temperature in control and prevent sudden changes.

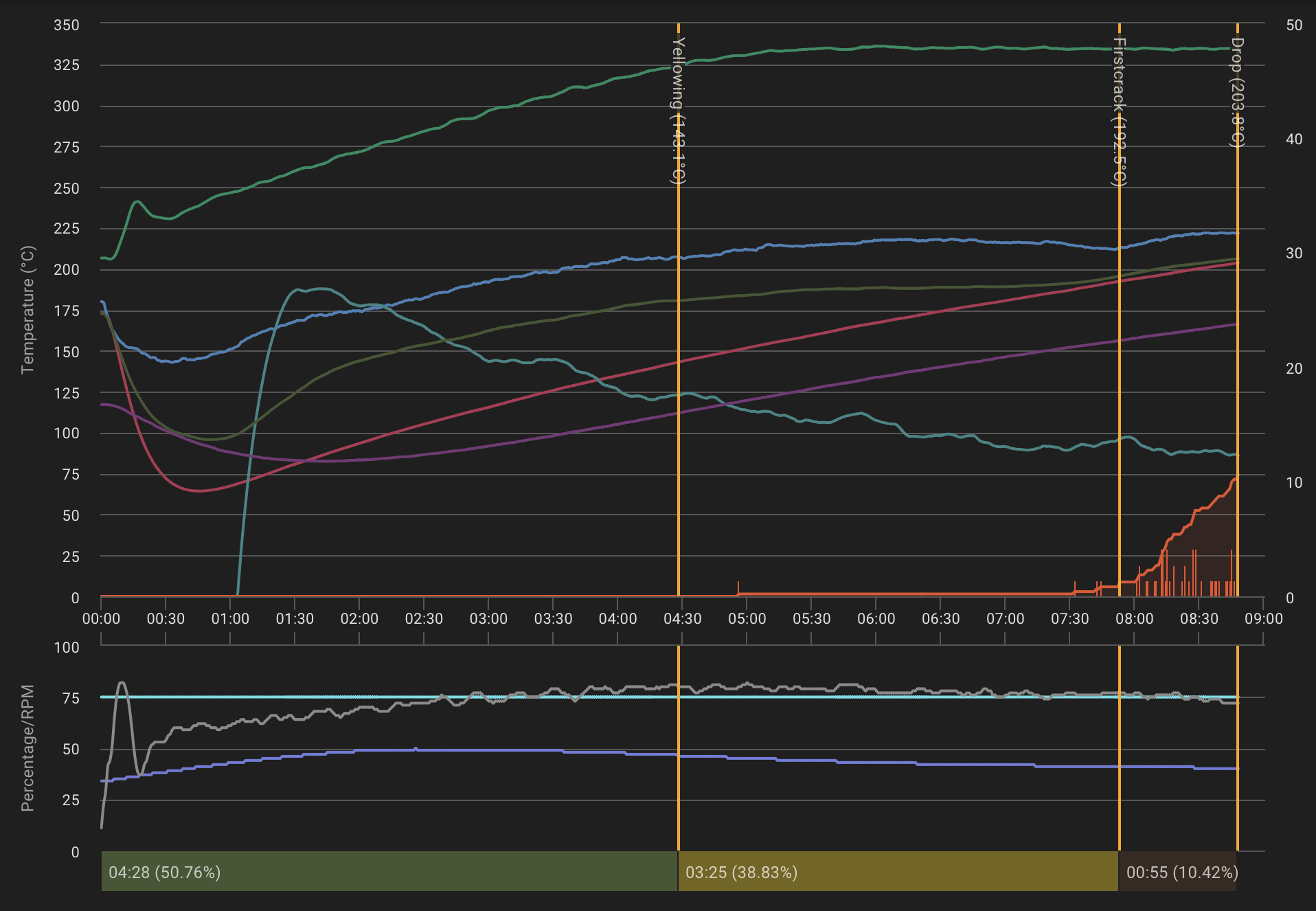

Live view example with temperature sensors available on S100 Plus. Red graph = bean temperature, blue graph = air temperature, green graph = inlet temperature.

Bean Temperature

The bean temperature sensor is placed in the center of the roasting bean mass. By monitoring this temperature, you can find out what’s happening during your roast, why it’s happening, and when. It can be used to ensure that everything is going according to the plan.

Bean- and air temperature sensors are included in every ROEST model.

Inlet Temperature

An inlet temperature sensor monitors the temperature that comes from the heating element and goes into the roasting chamber. It can significantly improve the roasting compared to power profiles due to higher precision. This type of sensor is, therefore, a good improvement, or in addition, for those who mainly use power profiles when roasting on a ROEST sample roaster.

Inlet temperature sensor is included in ROEST S100 Plus and L100 Plus.

More Data

Christian Castricone, a home roaster based in Switzerland, is the owner of a S100 Sample Roaster. The S100 has been meeting all his needs, yet after owning the roaster for quite a while, he is ready to take it to the next step. “If I were to choose again, I would go for L100 Plus due to the added sensors that allow more data.”.

Basic or Plus model?

The difference between the Basic and Plus models (S100 vs. S100 Plus and vs. L100 Plus) is the added First Crack Detection feature. If you opt for a basic model, you will have to listen and register the First Crack event by using the touch screen. *See the table for all the differences.

Download detailed list of technical specs here.

Differences

Additional Temperature Sensors

The L100 Plus has two additional temperature sensors; drum- and exhaust temperature.

In short, the drum temperature is the internal temperature of the drum when beans are added. This temperature should be adjusted according to the green beans’ density, moisture content, processing method, variety, and batch size. Analyzing the drum temperature can help you achieve the perfect roast, as a higher temperature can scorch the beans, and a lower temperature can result in baked coffee. The drum temperature sensor is needed to get the most out of the Between Batch Protocol feature.

The exhaust temperature measures the heat energy in the airflow exiting the roasting chamber. More specifically, it is the remaining heat energy input in the roasting mass, and collecting this data will help you understand more of what’s happening with the heat transfer.

The live view on L100 Plus shows graphs of the two additional sensors - drum temperature and exhaust temperature.

The extra sensors provided in L100 Plus allow further tracking and data collection when roasting. This makes L100 Plus ideal for professional quality control or scientific research; for example, Hard Beans in Poland uses it for scientific research about green coffee storage, the Research University of Zurich for various research topics, and the COMA project is currently conducting coffee research in Mexico to enhance specialty coffee quality in their market.

Between Batch Protocol

The L100 Plus also has the full version of the BBP feature, which helps you to achieve the most consistent roasts.

Between Batch Protocol is a way to reset the thermal energy in your roaster between batches. By using this profile on your ROEST Sample Roaster, you will have the same starting conditions as you had on your previous batch. When sample roasting, your main goal is to achieve the most consistent result on every batch. Using BBP with your chosen profile makes it more likely to get that.

Cooling Tray Warning

Thanks to the dual fan system in both models, you have the ability to roast back-to-back - meaning there are seconds in between each roast. How does it work? When the roast is finished and drops in the cooling tray, you simply charge a new batch while the previous is cooling down.

Now, this is where the Cooling tray warning comes in handy. This is a sensor that is only included in the L100 Plus model and alerts users to remove beans from the cooling tray. When operating a fully automated roaster, you might find yourself too focused on other important tasks of your job. Therefore, the sensor is beneficial as the machine will remind you to remove the coffee, in order to avoid mixing two batches.

Wood VS. Aluminum

Do you prefer the ultimate Scandinavian look with wood panels or the sleek and seductive black aluminum?

It might be tempting to choose based on the style. However, on L100 Plus you can choose between an aluminum design and heat-resistant PTFE handles, or go for the full Scandinavian style with wooden panels. So in terms of panels, you will need to ask yourself - where will I place the Sample Roaster while roasting? And most importantly, does the wooden/aluminum model include the features I require?

What’s the Verdict?

Both sample roasters provide you with plenty of roasting data: environmental and bean temperature, rate of rise, main motor speed, airflow, power, crack rate, and more. They can both roast automatically or with an advanced manual mode and help you improve roasting skills and coffee quality.

In the end, you’ll have to look at the differences and decide if additional sensors or aluminum panels will be needed for your business. It is crucial to determine what you want from your sample roaster in order to not overspend on features you won’t use or, conversely, miss out on valuable data that could help you.

If you do not intend to use drum temperature, exhaust temperature, or cooling tray warning, then S100 Plus will be enough to satisfy your sample roasting needs. On the other hand, if you’ve been wanting to collect more data and take your roasting to another level, then L100 Plus is a better choice. With extra sensors and more data to collect, L100 Plus has quickly become a preferred sample roaster for coffee professionals and scientific researchers.

-

We hope this article will help you make a final decision. If you’re still in doubt, do not hesitate to reach out to us by filling out a quotation form. We will get back to you with more information about the sample roasters and answer any questions you might have.

Wonder exactly how ROEST can help your business? Then check out these 5 reasons why.