How to select and buy green coffee beans

There are several factors that contribute to the overall green coffee bean quality. Therefore, it’s essential to recognize each factor from the very beginning - when you’re selecting and purchasing.

Despite the name, green coffee beans aren’t actually beans, but raw seeds from the coffee cherry. All of the coffee’s flavor potential is held within this green seed and is unleashed during the roast. This is when the beans change to their familiar brown color.

While green beans give you the opportunity to tweak the roast and flavor to your liking, you will not achieve a delicious roast unless these beans are carefully selected. The type and quality of the beans can easily determine whether it will be a tasty or a terrible cup.

There are several factors that contribute to the overall green coffee bean quality. Therefore, it’s essential to recognize each factor from the very beginning - when you’re selecting and purchasing.

Selecting the right green beans for you

There are numerous types of green coffee beans, and the differences between them affect both how the coffee tastes and how you should roast them. So if you’re not sure which green beans to select and want to find something to your liking - here’s what you need to consider:

Origin

Where do the green beans come from and at which farm did they grow? There are two reasons why you should know the answer to this. Firstly, each place will have different conditions, including soil, humidity and climate, which will have a big impact on the flavor and aroma of the coffee. Therefore, we suggest trying coffee from different countries and regions to compare in order to find a suitable coffee for you.

Secondly, being able to see which farm the coffee was grown at is usually a sign of a good quality batch. At times the packaging will only state the sub-region, meaning the green beans are most likely not from a single farm. We would not recommend buying these if you value unique characteristics and want the best quality.

Photo: Sucafina.

Altitude

Another key factor to consider is the altitude of where the green beans are grown. Generally, higher altitudes means lower temperatures. This leads to a slower growth - allowing the sugars to develop more. How does this affect the flavor? Well, the beans can gain more complex taste profiles, sweetness, and typically more acidity compared to those grown at warmer temperatures.

Processing

Processing refers to how the coffee seeds are removed from the fruit, and the chosen type of processing will have an incredible influence on the final taste of the coffee. So if you want to find a coffee to your liking, take a look at how the green beans were processed and choose one which produces a flavor profile that sounds good to you.

The two most popular methods are:

Natural (or dry) processing - involves drying out the entire freshly picked coffee cherry with the seed still inside, usually on raised beds in the sun. This method produces heavy-bodied, sweet, smooth and complex coffees.

Washed (or wet) processing - the seed is removed from the fruit before drying, which produces coffees that are cleaner, brighter, fruitier and more acidic.

An old tradition

Natural processing is considered a traditional method, which originated in places with limited access to clean water. Nowadays, it’s a much preferred method due to the flavor possibilities it yields.

Photo: Long Miles Coffee.

Appearance

You will need to ensure that the coffee beans are relatively uniform. The beans are normally sorted beforehand, however, if you buy coffee directly from farmers, the quality can often be quite inconsistent. You want to make sure that the green beans are similar in size and color. Why? The same color means they have been treated and ripened in similar ways - making them reach the same level of roast simultaneously. While beans of equivalent size will roast at the same speed. Therefore, selecting uniform green beans is important to achieve repeatable and consistent roasts.

Coffee importer Condesa continually check the health and quality of the green beans throughout the whole purchase process. Photo: Condesa Co.Lab.

Ethical Coffee

Despite the fast-growing coffee industry, many of the hardworking coffee farmers remain underpaid and lack the safety equipment needed. This is why it’s essential to buy ethical coffee in order to protect the rights of coffee farmers.

Hence, if you do not have the ability to buy directly from farmers, we suggest selecting importers with a reputation for sourcing beans in a way that is fair to the workers and doesn’t harm the environment. The importer should be committed to transparency and provide full traceability of the green coffee.

“Ask the hard questions - ask your importers about who else is involved in the value chain, who received what percentage of the price you pay, ask them about farming practices and conservation efforts - these things matter!”

- Katja Klein, Founder of Kontext Coffee Company

Try a range of different coffees and take notes on each one to develop an idea about which coffees you prefer. Photo: Nordic Approach.

So where can you buy green beans?

Online retailers

Purchasing green beans online is easy and provides a varied range of green beans from all over the world. Have you tried Sweet Maria’s? They have a huge selection of green beans available in an extensive array of flavors, profiles, processing methods and bean types.

Importers

Need green beans for your coffee shop or roastery? Then a common practice would be to purchase from importers, who usually have a larger network and financial means to buy various green beans in large quantities. Importers will provide information about each producer they are working with, and have all the resources to handle bulk logistics and international duties - making the process more seamless for the buyer.

Currently looking for a reliable importer offering high quality green beans? Then we have some suggestions for you. Click to read more about them, check out their offer list and try their roasting profiles:

Get inspired by ROEST roasting profiles

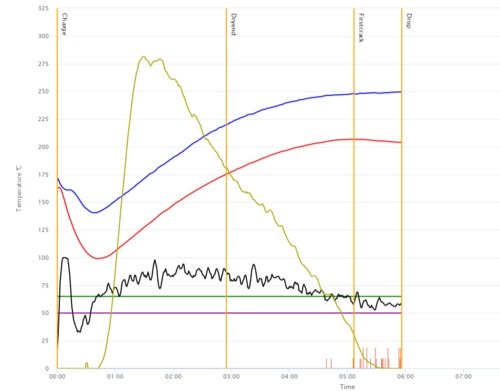

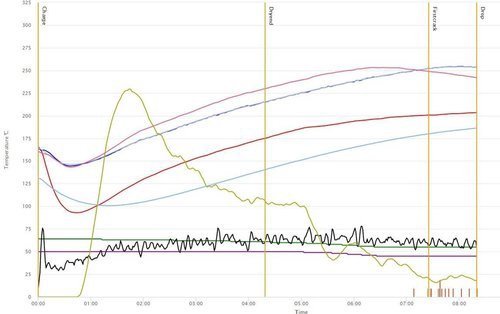

Roasting profile 1 - Sucafina Profile Washed

Suitable for Kenya, China, Ethiopia Washed, Colombia Washed, Indonesia Wet-Hulled also Uganda Natural.

Roasting profile 2 - Condesa Brazil Natural “Low and Slow”

The profile works well for natural and more experimental processes with challenge of lower density beans with dryer moisture and water activity readings.

Direct trade

If you want to take it further with no intermediaries such as importers, then it is possible to buy directly from producers. This leads to better traceability and transparency. You can visit the farm, establish a relationship with the workers, and spend time evaluating the coffee before buying. Arnold Ilves, Production Manager at Coffee People, provided us a great advice regarding this method:

“Get some samples from a green coffee seller. If you see what you like then check where the farm is located and go visit the region for a couple of weeks. Try to make contacts there to find out where to buy more coffee. We have tried it. It works! It will make a hell of an adventure as well.”

- Arnold Ilves, production manager at Coffee People

The next step

You got green beans, now what? It’s time to start roasting and evaluating! Learn more about how to cup HERE.

Learning to ROEST with Long Miles Coffee Part1

For over a decade roasting technology has evolved significantly: new roasting technology, roasting techniques,… We are even able to share roasting profiles. David Stallings from Long Miles Coffee shares his roasting journey from gas roasters and spreadsheets to today’s technology that led him to “the most perfect small-scale machine yet“. Read more in the article written by David Stallings.

For over a decade roasting technology has evolved significantly: new roasting technology, roasting techniques,… We are even able to share roasting profiles. David Stallings from Long Miles Coffee shares his roasting journey from gas roasters and spreadsheets to today’s technology that led him to “the most perfect small-scale machine yet“.

Over to David:

Long Miles Coffee is an East African Coffee producer with washing stations in Burundi. Photo credit Long Miles Coffee.

My name is David Stallings and I handle Roaster Relations for Long Miles Coffee. Long Miles is an East African coffee producer. We own two Washing Stations in Burundi, are currently in the process of building a third in that beautiful landlocked country, operate a washing station in Kirinyaga County on Mt. Kenya, and are getting ready to formally launch operations in Uganda.

Beginnings of roasting logs

I first learned to roast coffee in 2008. I recently came across some computer spreadsheets with profiles from those early days and, in truth, was pleasantly surprised by my early efforts in coffee roasting. Why were these notes in the form of spreadsheets? Because these were the days before the ubiquitous use of data logging software. A small handful of vanguard and more technologically advanced specialty roasters had developed their own software to automatically log roast data. The rest of us were left to do the best we could with notebooks, spreadsheets, and other forms of manual data logging. The spreadsheets I recently stumbled upon had temperature data points recorded every 30 seconds of the roast. From there I made graphs of the profiles in Microsoft Excel in order to have a visual representation of the roasts. My employer at the time thought I was a fool, saying that one only needed to look at the bean temperature every two minutes or so in order to produce consistent results.

“Learning to use the ROEST sample roaster has put a point on so many of the techniques and theories which I have developed and thought over as a coffee roaster this past decade-plus.”

Missing knowledge

Similar to how many baristas were trained in the earlier days of specialty coffee, roasting was taught to me in terms and technique that straddled the line between craft and science. While many would still argue that this is the case (I, myself, admit some partial truth to this sentiment), I believe that many of us see now, with better tools and techniques for evaluating and controlling roasts, that what we chalked up to craft previously, was really the inability to produce consistent roasts through lack of knowledge and nascent tools. In some ways, learning to use the ROEST sample roaster has put a point on so many of the techniques and theories which I have developed and thought over as a coffee roaster this past decade-plus.

David Stallings, responsible for Roaster Relations at LMC, is truly enjoying roasting on his ROEST sample roaster. Photo credit Long Miles Coffee.

The older the better - or not at all

Like many who have been in specialty coffee for a decade or more, I learned to roast on a traditional drum roaster. For the first chunk of my roasting career, fluid bed and/or hot air roasters were relegated to low-quality and/or smaller roasting operations. Nearly every up-and-coming roasting company that I knew around 2008-2010 was focused on obtaining or singing the praises of traditional drum roasters - the mindset in those days frequently being ‘the older the better.’ While many are still roasting on these machines (and in some cases to very good effect), the rise of fluid bed and/or hybrid hot air/drum machines has been undeniable. This is especially true for roasters looking to perfect very light and yet fully-developed roast profiles.

I feel fortunate to have had an education and roasting evolution that has spanned a number of machines and machine-types. The evolution of my roasting knowledge has not been linear, starting with traditional drum roasters and moving to fluid bed/ hybrid hot air/ drum machines. Different machine types have informed each other and the knowledge I have garnered on one machine has been applicable to others and vice versa. The ROEST sample roaster may be the most perfect small-scale machine yet designed to explore the many different aspects of coffee roasting that I learned about through various different roasting systems. The capability to develop profiles based on different parameters and the machine’s ability to develop coffee remarkably evenly, coupled with its ease of use and maintenance, make it an essential tool in my professional life.

Sample of Natural coffee by Long Miles Coffee from Heza hills. Photo: Long Miles Coffee.

In 2020 Long Miles Coffee started to roast their samples on ROEST sample roaster. Photo: Long Miles Coffee.

Profile Development

With any new machine there is always a period during which one needs to find their footing, so to speak. I have even found this to be true when roasting on different machines of identical make and model. This is true for any number of reasons:

stack height

proximity of tall buildings to stacks that may cause negative or positive pressure in the stack

probe type

probe age (and cleanliness)

exact probe placement

gas pressure and consistency, etc.

As such, I never expect my initial roasts to be particularly fruitful. That said, I do expect them to tell me much about the machine.

Interested in Profile Development? Read on our blog: Developing roast profiles with Matt Winton.

ease of learning through SAMPLE ROASTER

One aspect of technology’s increasing influence in coffee that I am particularly excited about is roast profile sharing. Though there are obvious implications for this feature that I can and will touch on later, I also greatly appreciate the effect this has when it comes to flattening the learning curve associated with a new machine. By knowing how others (including the manufacturer themselves) like to utilize the piece of equipment, I am -firstly- given a rapid glimpse into the norms and standards for the equipment and -secondly, and more importantly- I am able to greatly shorten the aforementioned period of finding my footing.

Upon getting the ROEST sample roaster up and running for the first time, I decided to run a few profiles that were readily available to me. Among these were roasting profiles designed by the team at Roest, profiles designed by Tim Wendelboe, and profiles designed by the team at Nordic Approach. Having names I trust and respect back not only the sample roaster I was about to roast on, but even the profiles I was about to run made for a welcome level of faith in the process.

DAVID STALLINGS

ROASTER RELATIONS for LONG MILES COFFEE

Prior to working with Long Miles David launched the North American sales office and did sourcing for the Oslo based importer The Collaborative Coffee Source. Before those roles he launched the green and roasted coffee programs at Passenger Coffee in Lancaster, Pennsylvania and Parlor coffee in Brooklyn, New York.

How to evaluate the quality of your coffee. Part 2: Sample Roasting

What sets speciality coffee apart from any other grade on the market is the quality. To ensure it is delivered in the hands of your customers, there is a meticulous process every coffee business needs to follow. How should the Quality Control look like and what procedures are required? Read the article by Julia Rebecca Richardson.

Sample roasting is an essential component of the quality control process at all aspects of the supply chain, all the way from origin. This is helpful for buyers, producers, importers and roasters. To ensure high quality of your coffee, there are important steps to follow in your sample roasting process. Step number one: purchase the right sample roaster. Before you take this step, read the words from Julia Rebecca Richardson, coffee professional with years of experiences in QC (Quality Control) lab at a coffee import company.

Over to Julia:

Why sample roasting is important

Sample roasting is an opportunity to evaluate the quality and uniformity of the green coffee. This can provide valuable feedback to producers, showcase coffee to potential buyers, aid in production development processes, as well as quality assurance on inventory checks, age, and any profile changes that need to be made.

Sample roasting serves two main purposes:

1.

Roasting 50 g-150 g of coffee in an uniform, consistent manner to evaluate any possible defects, faults or flaws in the coffee, and to have an overall understanding of the cup.

2.

Roasting 50 g-150 g of coffee in such a way as to highlight characteristics in the coffee for sales or product development purposes.

Julia evaluating coffee after sample roasting. Sales purpose: looking for which lot to buy for the client.

Speaking of the purpose…

Quality

When evaluating coffee for quality purposes, it is important to have a consistent, non-biased and uniform roast to concentrate on the attributes of the coffee versus the roast profile. The main goal of this process is to uncover any defects or flaws of the coffee that were not revealed in the previous green bean evaluation.

Sales

For sales purposes, sample roasting can highlight specific characteristics of the coffee such as sweetness, acidity, balance, etc., to showcase the coffee potential to the buyer.

Production

For production purposes, sample roasting can be used for quality control, understanding how the coffee reacts to the roasting process, or for revealing the potential of the coffee.

Read more about how Tim Wendelboe uses his ROEST sample roaster within different departments of his business: Sample Roasting with ROEST by TW

The best sample roaster

Some of the key components of a sample roaster by Julia:

Uniform heat distribution

Temperature sensors (temperature inside the drum and bean temperature)

Measurable and adjustable airflow/fan

A trier to have visual contact (on the photo below)

Live view, data logging and profiling

Fast cooling, ideally in a separate cooling tray

Roasting on ROEST sample roaster you have a visual contact with your beans during roasting using a trier.

Let’s take a closer look on it:

Size matters

A good sample roaster needs to be small enough to consistently roast a 100 g sample at quality standards, and needs to have the capacity to manage the roast within the quality control timeframe protocols.

CONSISTENCY

Whether you’re using the sample roaster a few times a week or a 100+ roasts a day, it is important that the roaster remains consistent with each roast. It should be able to provide an even coffee bean development repetitively, therefore producing a clean and balanced cup.

EFficiency

As a Quality Control Manager there are many tasks to follow between roasts, therefore, having a sample roaster that recovers quickly between the roasts and has enough features to free your hands to do other tasks is amazing! It’s about finding a balance, a great sample roaster would have some autopilot features, but enough basic features to give room for manual operation and creativity.

EASY & INTUITIVE

Personally, having worked with both solid drum and digital micro-roasters, a dependable, uniform, quick and easy to use sample roaster is preferable. Ideally, a good sample roaster would have a trier for a visual check of colour and to follow how the coffee is reacting to heat and air flow. The sample roaster should also be able provide an even coffee bean development repetitively, therefore producing a clean and balanced cup.

Efficient workflow of sample and production roasting at the same time. Head roaster Ludwik at Fuglen Coffee Roasters in Oslo.

Read also about key values of sample roaster by Nordic Approach.

“ROEST can reduce the airstream to a much lower volume than a fluid bed roaster - increasing the control over the roasting process. ”

Drum roaster or fluid bed?

Both have their pros and cons. This is where the ROEST sample roaster comes in. ROEST is not a traditional/conventional drum roaster. It is a hybrid of both technologies: small hot air roaster and conventional open drums. While the drum is fixed, paddles inside are agitating the coffee, and heated air passing diagonally across the roasting chamber heats up both the drum and the coffee. Since the coffee is agitated by paddles, not by high pressured air, like a fluid bed roaster, ROEST can reduce the airstream to a much lower volume than a fluid bed roaster - increasing the control over the roasting process.

Approach to sample roast profiles

Follow the live view, log your notes notes, create your own profile, and share with others. ROEST has its own user-interface webportal.

When looking for the ideal roast profiles for sample roasting, I like to have verified profiles that provide a base. I then use temperature readings as a guide, engaging with the coffee by checking the colour, smell, surface development and time, and then adjusting heat and airflow accordingly. I also make necessary changes depending on the moisture reading, bean density, origin, process, etc.

In the age of technology, connectivity to digital devices for roasting and recording profiles is a big advantage. It is great to be able to share profiles with customers, partners and colleagues. Having the opportunity to digitally take notes and record changes in the roasts is also helpful in order to make necessary changes for the next time.

Read more about Creating 50g profile - detailed report by Blazej Walczykiewicz.

My routine step by step

After the green bean physical evaluation is completed and documented, you begin roasting! I like to roast between 100 g to 120 g, that way there is enough material for a proper evaluation in-house, and there is enough coffee left for potential buyers and customers.

CLEAN & QUIET

I always like to begin and end with a clean lab. Ensure your roaster is clean of old chaff and debris and that the area is well lit. Quiet surroundings are ideal, however, having worked in a lab that shared a roastery and packing production, I understand silence is not always a possibility. That is why First Crack detection is so extremely helpful: even if the cracks are subtle, ROEST can register them for you.

Charge the beans and go back to labels and preparing other green samples. ROEST will take care of the roast for you.

TURN ON & CHARGE

Once the area has been cleaned, I turn on the roaster and warm up the machine. I then start the process of roasting. With ROEST, I am able to charge the beans, roast, and first crack detection will start the development time by itself, then drop the roast in the tray when completed. Then all I need to do is charge the next batch of greens. There is no need to wait for the roaster to reheat, as ROEST goes up to the starting point within 2 seconds and cools down super fast.

IT’S ALL ABOUT THE WORKFLOW

In the meantime, while I am roasting I am able to set up different areas of workflow. My computer is nearby for data entry and checking emails in between roasts, a scale and cupping trays for weighing up greens to go in next and labels are printed. Once the coffee has cooled down and has reached room temperature they’re packed in a dark, resealable bag with a label.

CRAFT (BUT MIND THE RULES!)

I personally view sample roasting as a craft, and the more you do it, the more you understand the coffees, different variables, and the equipment you are using. However, for starting out a basic rule of thumb is setting up perimeters around the SCAA (Specialty coffee Association) guidelines.

The roasting of coffee for cupping shall take between 8 and 12 minutes, and the cupping should take place between 8 and 24 hours after roasting.

Scorching and tipping should not be apparent.

The sample should immediately be air cooled.

Samples should be stored in a cool and dark place, but not refrigerated or frozen.

The colour should be light to medium light, comparing to either an Agtron colour tile #55 or an Agtron machine using grounds for accuracy aiming for a reading of 63 (+/- 1).

After the appropriate resting period is completed, it is finally time to cup the coffee! The article is following in the Part 3 - here.